The heat transfer loop component is developed firstly to facilitate the simulation of water-to-air heat pump (WAHP) systems in VE 2012 (v6.5). In this first phase, the heat transfer loop must serve water-to-air heat pumps. It will eventually be extended to support heating, cooling, and collecting or rejecting heat via hot/cold-water coils on the airside network and to serve the purpose of transferring heat between other water loops (heat transfer loops, chilled water loops, hot water loops, etc.).

Water-to-air heat pump systems

A water-to-air heat pump system consists of multiple zone-level water-to-air heat pumps connected to a common water loop. The common water loop is used by each individual heat pump as a source for acquiring heat or sink for rejecting heat. Some of the WAHP units on the loop may be in cooling mode, while others may be in heating mode. For all WAHP units on given Heat transfer loop, this common loop simultaneously acts a resource for any WAHP in heating mode and a sink for any AWHP in cooling mode.

A conventional WAHP system uses a boiler to add heat to the common loop and a cooling tower or fluid cooler to reject excess heat from the common water loop. This is also is referred to as a “water-loop heat pump” (WLHP) system, and the WAHP model includes a set of WLHP performance curves for this type of application. Typically, the boiler operates to maintain the minimum loop supply water temperature around 68°F (20°C), while the cooling tower or fluid cooler operates to maintain the maximum loop supply water temperature of something like 86°F (30°C). Between the maximum and minimum, the loop supply water temperature is allowed to float.

A ground-water WAHP system uses an open water loop that draws water from a lake, well, or similar resource. The WAHP model includes a pre-defined set of GWHP performance curves for this type of application. The loop water temperature is assumed to float with both the loads and the lake/well water temperature, with the latter represented as an annual temperature profile on the source side of a water-to-water heat exchanger. Typical rating conditions in terms of water loop temperatures for this type of system are 50°F (10°C) for heating and 59°F (15°C) for cooling.

A ground-source heat pump system uses a closed loop of polymer tubing acting as a “geo-thermal heat exchanger”. The loop water temperature floats with the ground temperature, loop load, and the characteristics of the geo-thermal heat exchanger. Typical rating conditions in terms of common water loop temperatures for this type of system are 32°F (0°C) for heating and 77°F (25°C) for cooling. User should be cautioned, however, that this model does not include detailed geo-thermal heat exchanger characteristics or the capacitance or thermal mass of the earth around the tubes, and therefore has no means of determining the extent to which this earth may become thermally depleted or saturated over time. So, while this model can be used to represent a ground-source heat pump system, it is limited to representing that which can be suitably described by a seasonal ground-source temperature profile. For more detailed modeling of ground-source heat pump systems, including characteristics of bore fields and geo-thermal heat exchangers, see Appendix D: Ground-Source Heat Pump Modeling using ApacheHVAC loads and Gaia Geothermal Ground-Loop Design.

Two components are provided for modeling WAHP systems:

· Water-to-air heat pump

· Heat transfer loop

The WAHP units must be connected to (served by) a common Heat Transfer Loop (HTL) by selecting the appropriate HTL within the heating/cooling coil dialogs. Details of the Water-to-air heat pump component and modeling are covered in section 2.9. This section provides details for the Heat transfer loop component.

Heat sources (or sinks) available on the heat transfer loop may include the following:

· For heating: solar water heater (SWH), water source heat exchanger (WSHX), condenser heat recovery (CHR), air-to-water heat pump (AWHP), combined heat and power (CHP), sequenced heating equipment set

· For cooling: water source heat exchanger (WSHX), cooling tower (CT) or fluid cooler (FC)

Note that the ground-water heat pump implementation in this phase is intended for modeling ambient- and ground-water sources (oceans, rivers, lakes, ground water, wells, etc.) with a constant or readily profiled water temperature. If you choose to use this component to model a ground loop above the water table (i.e., a “geo-thermal heat exchanger”), please be aware that this will not include a dynamic model of the ground mass as a source and sink to be thermally depleted and recharged over time. For more detailed modeling of ground-source heat pump systems, including characteristics of bore fields and geo-thermal heat exchangers, see Appendix D: Ground-Source Heat Pump Modeling using ApacheHVAC loads and Gaia Geothermal Ground-Loop Design.

Heat transfer loop configurations

Two options are offered for the Heat transfer loop configuration:

· Primary-only : Loop flow is maintained by a primary pump that can be either a variable-speed pump (i.e., using a variable-speed drive) or constant-speed pump riding the pump curve.

· Primary-Secondary : Loop flow is maintained by a combination of primary and secondary pumps. The primary pump is assumed to have constant flow when it is on. The secondary pump can be either a variable-speed pump with VSD or a constant-speed pump riding the pump curve.

Selecting the Primary only configuration effectively removes the constant-speed primary loop pump from the diagram in Figure 3-35 .

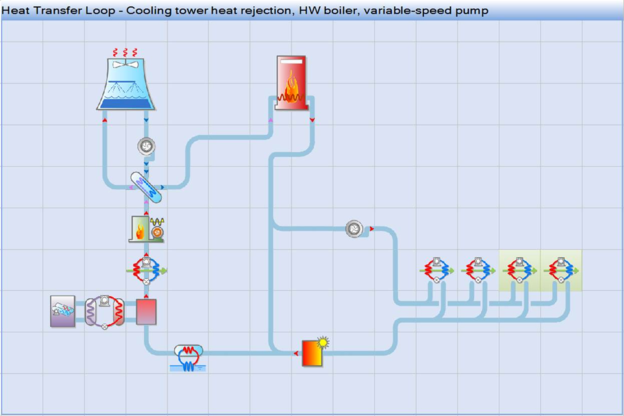

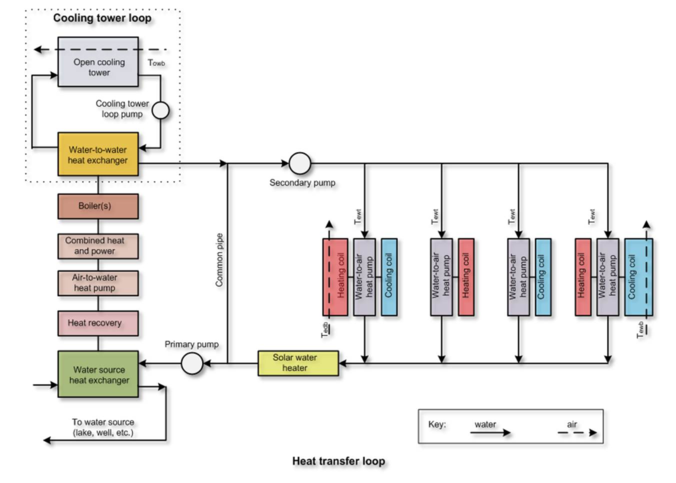

Figure 3 - 35 : Heat transfer loop with primary-secondary configuration, a range of optional heat acquisition and heat rejection devices, and zone-level water-loop (water-to-air) heat pumps . The fluid cooler alternative to the cooling tower and available heat recovery connections are not shown.

Figure 3-35 shows the conceptual heat transfer loop configuration. In this configuration, the heat transfer loop uses a primary-secondary loop configuration. On the secondary loop, source water is supplied to multiple water-to-air heat pump units connected in parallel. Water-to-air heat pump units are used to serve both simple heating coils and simple cooling coils. A optional solar water heater can be included on the return side of the secondary loop, downstream of the heat pumps (i.e., as a pre-heating source on the secondary return pipe).

On the primary loop, there are five optional heat sources connected in a pre-defined series configuration. These heat sources could include: WSHX (water source heat exchanger), HR (Heat recovery), AWHP (Air-to-water heat pump), CHP (Combined heat and power), and sequenced boiler(s) or similar equipment in a Heating equipment set. Each of these, when included, adds heat to raise the loop water temperature to the supply water temperature set point. If the first device in line to do so does not achieve the set point, the next device in series after it will have the opportunity to address the remaining load.

There are also heat rejection devices connected in series on the primary loop. These heat rejection devices can include: WSHX (water source heat exchanger) and cooling tower or fluid cooler. The water source heat exchanger, as noted above, can also function as a heat source. The modeling and dialog are set up to assume that the WSHX is a single device that may, if desired, operate in both heat-acquisition and heat-rejection modes. The cooling tower option comprises a separate loop with open cooling tower, water-to-water heat exchanger (WWHX), and cooling tower loop pump. The cooling tower loop is thus connected to the HTL through the WWHX, which is included to reflect the real-world need to prevent contaminants from entering the HTL. The cooling tower loop with pump and heat exchanger can alternatively be replaced with a fluid cooler, as waterside of the fluid cooler is fully contained within its integral water-to-air heat exchanger. rejecting heat to cool down the source water return temperature to source water supply temperature set point when needed.

Loop control and sequencing

The loop water returned from each of the WAHPs served by a particular heat transfer loop (each with its own return water temperature and required flow rate) is mixed at the loop return pipe to provide the overall loop return water temperature. The loop return water temperature is then compared with the target loop supply water temperature set points to determine the loop operating mode, as the following:

· If any WAHP served by a particular heat transfer loop is operating (extracting heat from or rejecting heat to the HTL), the system and loop flow will be turned on.

o If the return water temperature is lower than the loop heating supply water temperature set point, then the loop will operate in heating mode.

o If the return water temperature is higher than the loop cooling supply water temperature set point, then the loop will operate in cooling mode.

o If the return water temperature is between the loop heating and cooling supply water temperature set points, then the loop temperature will be allowed to float between these setpoints without engaging or loading any of the system-level heat acquisition or heat rejection devices.

· If no WAHP served by a particular heat transfer loop is currently operating, the loop, and hence the entire system, will remain off.

Heating mode operation

The heat acquisition sequence on a heat transfer loop, assuming all possible pre-heating devices are present, is as follows: SWH à WSHX à CHR à AWHP à CHP à Heating equipment set . Unused pre-heating devices will be skipped in the loading sequence.

When included, the sequenced Heating equipment set associated with a heat transfer loop meets remaining load after heat available from any included solar water heater (SWH), water source heat exchanger (WSHX), condenser heat recovery (CHR), air-to-water heat pump (AWHP), or combined-heat & power (CHP) system have been fully utilized. Heat available from any of these devices (SWH, WSHX, CHR, AWHP, and CHP) is thus used to meet the load prior to engaging the sequenced equipment in the Heating equipment set (see Heating equipment set sub-tab of the Heat acquisition tab in the Heat transfer loop dialog).

Cooling mode operation

When included, the WSHX is loaded first to meet the imposed cooling load. Any load remaining after the WSHX is met by loading the available cooling tower or fluid cooler. Note that it is possible for a WSHX on a heat transfer loop to operate in both heating and cooling modes, depending on the relative temperatures of the HTL water and WSHX source water.

Loop capacity and feedback to WAHPs

If the loop heating or cooling load exceeds the combined capacity of all heating equipment and heat acquisition and rejection devices available on the loop, any deficiency in overall heat transfer loop capacity will result in a deviation of the loop supply water temperature from the loop heating or cooling supply water temperature set point. HTL supply water temperature thus provides feedback to the WAHPs. In other words, while heating or cooling sources on a Heat transfer loop will always attempt to achieve the target supply water temperature, this may not be feasible under all simulated conditions. If the target supply water temperature range on the HTL cannot be maintained, the WAHPs served must attempt to meet heating or cooling loads with cooler or warmer water.

The WAHPs served by the HTL will respond to the adjusted loop supply water temperature in its capacity and efficiency calculations, as the loop supply water temperature features as one of the independent variables in the WAHP performance curves.

Heat transfer loop sizing procedure

The sizing approach used for the heat transfer loop differs from that of the chilled water and hot water loops, which always use the chiller or heating equipment set, respectively, as the primary sizing target. The sizing approach used for the HTL is to have the user nominate the Principal equipment for sizing from amongst the heating and cooling sources on the loop, and make this the focus for sizing operations.

For heating, the Principal equipment for sizing may be a sequenced heating equipment set, a water-source heat exchanger, or an air-to-water heat pump; however, it may not be a solar water heater, which is not amenable to sizing by any simple procedure. The ‘principal equipment’ will be sized to provide the entire loop heating load (and subject to the oversizing factor in the main HTL tab). Other devices feeding heat into the loop are sized to a specified percentage of the loop heating capacity. The Current loop capacity is the heating capacity of the principal equipment (which may have been manually edited).

Cooling sizing proceeds along similar lines. Here the ‘principal equipment’ may be a cooling tower with heat exchanger, fluid cooler, or water-source heat exchanger.

Based on this approach, in the system-level ASHRAE Loads autosizing run (Analysis type = ApacheHVAC system loads), two design loads will be calculated for the heat transfer loop:

a) Design heat acquisition load for heating

b) Design heat rejection load for cooling

Firstly, the design heat acquisition load for heating and design heat rejection load for cooling will be used to update the respective Autosized loop heating and cooling capacities in the HTL tab of the HTL dialog.

Secondly, the two design loop loads are translated according to relative capacities set for the individual heating and cooling devices on the loop. Capacities are updated for the Principal equipment for sizing and for any other devices for which the Autosize… checkbox is ticked. This can be summarized as follows:

· Heat acquisition load (loop heating capacity)

o 100% + oversizing factor goes to the principal heating equipment (it will be sized to meet the entire loop heating load).

o User specified percentage × (100% + oversize factor) goes to other heat acquisition devices that are present and designated for autosizing.

· Heat rejection load (loop cooling capacity)

o 100% + oversizing factor goes to the principal cooling equipment (it will be sized to meet the entire loop heat rejection load).

o User specified percentage × (100% + oversize factor) goes to other heat rejection devices that are present and designated for autosizing.

Whether or not the capacity for an individual heating or cooling device will be updated with the autosized value depends on the status of its corresponding Autosize… checkbox. If this checkbox is ticked for a device, its capacity will be updated with the autosized value. If this checkbox is not ticked for a device, its capacity will not be updated with the autosized value.

In addition to the capacities for the heat transfer loop and individual heating and cooling devices, the following two design temperatures will also be updated after a system sizing run:

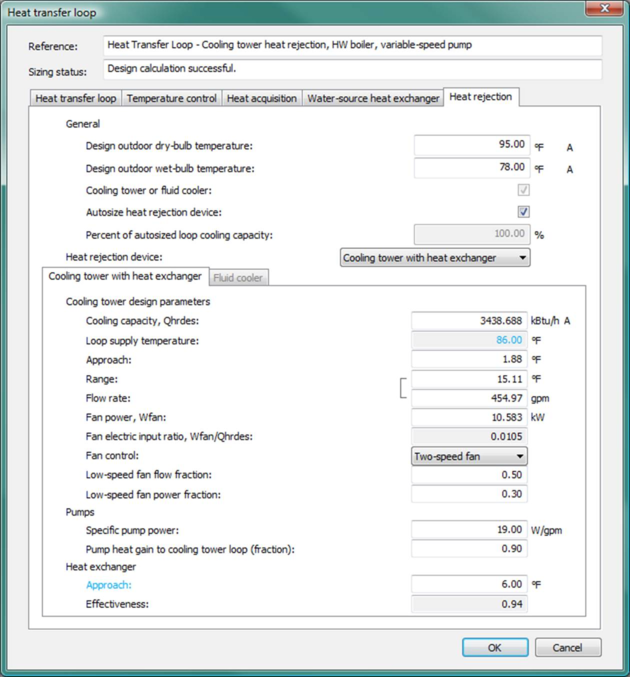

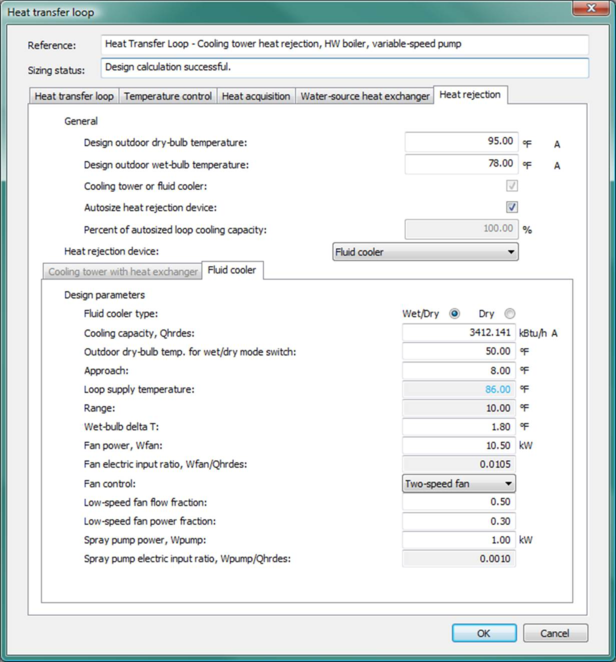

· Design outdoor dry-bulb temperature on the Heat rejection tab of the HTL dialog

· Design outdoor wet-bulb temperature on the Heat rejection tab of the HTL dialog

Heat transfer loop pump modeling

As noted above, there are two options for the Heat transfer loop configuration:

· Primary-only : Loop flow is maintained by a primary pump that can be either a variable-speed pump (i.e., using a variable-speed drive) or constant-speed pump riding the pump curve.

· Primary-Secondary : Loop flow is maintained by a combination of primary and secondary pumps. The primary pump is assumed to have constant flow when it is on. The secondary pump can be either a variable-speed pump with VSD or a constant-speed pump riding the pump curve.

For both Heat transfer loop configurations, pumps are assumed to operate whenever at least one WAHP unit served by the HTL is operating—i.e., whenever there is heat rejection to or heat acquisition from the HTL . Otherwise, all pumps remain off and there is no water loop flow.

If the pump has a constant flow when it is on, as is true for the primary pump in the Primary-Secondary configuration , this constant flow is multiplied by its specific pump power to determine the pump power. If the pump has variable flow, which can be the case for the primary pump in the Primary-only configuration or the secondary pump in the Primary-Secondary configuration, i ts design pump power is calculated as the specific pump power multiplied by the design water flow rate. The design pump power is then modified by the pump power curve to get the operating pump power. If a pump has variable flow it will be subject to cycling on/off below the minimum flow rate permitted.

The variable flow featured in the pump power curve is calculated as the sum of flow required from all WAHPs served by the heat transfer loop, subject to the minimum flow permitted for the pump. Required water flow rates for the WAHPs vary in proportion to their heat rejection or heat acquisition loads.

When the Primary-only configuration is selected for the Heat transfer loop, this effectively removes the constant-speed primary loop pump from the diagram in Figure 3-35 .

Heat transfer loop distribution losses and pump heat gain

Distribution losses from the pipe work are considered as a user-specified percentage of the heat transfer loop load. Transfer of loop pump heat gain to the loop is modeled according to a user input fraction for pump and motor heat gain to the heat transfer loop.

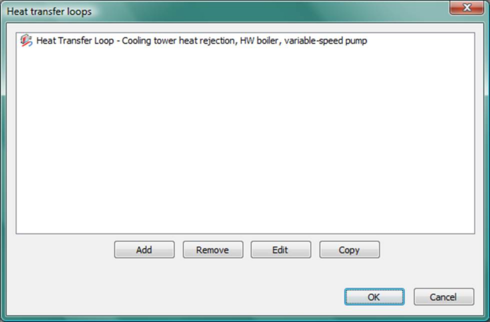

Heat transfer loops dialog

The heat transfer loops tool provides access to adding, editing, copying, and removing named heat transfer loops.

Toolbar button for Heat transfer loops .

Clicking this toolbar button opens up the Heat transfer loops dialog (shown in Figure 2-36), which manages the list of heat transfer loops . A heat transfer loop may be added, edited, removed, or copied through the corresponding buttons in this dialog. Double clicking on an existing heat transfer loop, or clicking the Edit button after selection of an existing heat transfer loop , opens the Heat transfer loop dialog (shown in Figure 2-37) where parameters for the selected loop may be edited.

Figure 3 - 36 : Heat transfer loops dialog shown with illustrative default loop included with the pre-defined systems in VE 2012 (v6.5).

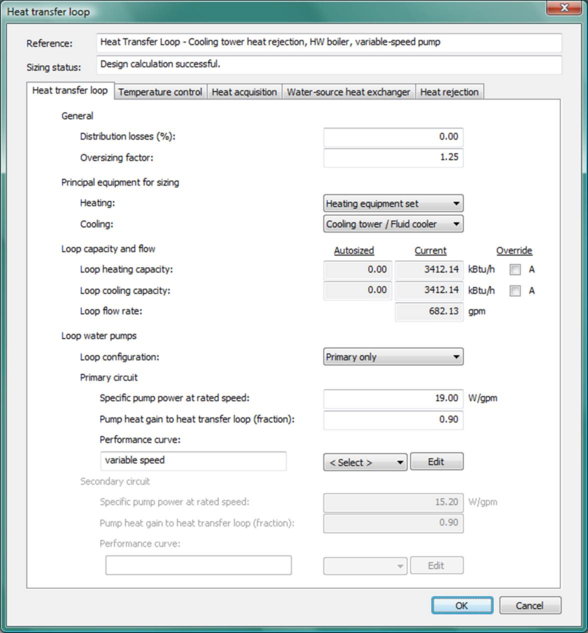

Heat transfer loop dialog

The Heat transfer loop dialog has five tabs:

· Heat transfer loop : This tab manages the properties of the heat transfer loop. It provides inputs for the loop principle equipment for sizing, information on loop capacity and flow, as well as inputs for the primary and secondary loop pumps.

· Temperature control : This tab provides inputs for the loop temperature controls.

· Heat acquisition : This tab manages information used for all devices available for adding heat to the loop (SWH, CHR, AWHP, CHP, and Heating equipment set), except for the WSHX, which can be used as both heating and cooling source and is presented on its own in a separate tab.

· Water-source heat exchanger : This tab provides inputs for the WSHX, which can be used to add heat to or reject heat from the loop.

· Heat rejection : This tab manages information used for heat rejection devices (cooling tower or fluid cooler) on the loop, except the WSHX, which can be used as both heating and cooling source and is presented on its own in a separate tab.

Figure 3 - 37 : Heat transfer loop dialog shown with the Heat transfer loop tab selected.

Reference name for Heat transfer loop

Enter a description of the component to aid in selecting and referencing any component or controllers within other dialogs and in the component browser tree. Reference names should be informative with respect to differentiating similar equipment, components, and controllers.

Sizing status

The sizing status is an informative field indicating whether the design calculation is feasible for the current settings of all relevant heat transfer loop input parameters.

The sizing status is checked and updated instantaneously in response to any changes on the parameters that the following derived parameters depend upon, provided that these derived parameters are active (enabled):

a) Loop flow rate in the HTL tab

b) HX design approach and design effectiveness in the WSHX tab

c) Fluid cooler or cooling tower design approach in the Heat rejection tab

d) Cooling tower HX design approach and design effectiveness in the Heat rejection tab

For the above derived parameters to be considered as feasible:

a) HTL loop flow rate should be > 0.0;

b) WSHX design approach should be ≥ 0.0 K;

c) WSHX design effectiveness (ɛ) should be: 0.0 ≤ ɛ ≤ 1.0;

d) Fluid cooler design approach should be ≥ 0.01 K;

e) Cooling tower design approach should be ≥ 0.01 K;

f) Cooling tower HX design approach should be ≥ 0.0 K;

g) Cooling tower HX design effectiveness (ɛ) should be: 0.0 ≤ ɛ ≤ 1.0;

When an individual derived parameter is feasible, it is displayed in black text. When all of the above derived parameters are feasible, the sizing status field displays “Design calculation successful.”

If any of the above derived parameters is infeasible (out of range), the infeasible derived parameter is displayed (on the interface) in red text, and the sizing status field displays “Design calculation failed. The parameters in red are out of range.” in red text.

Heat transfer loop tab

The Heat transfer loop tab facilitates the definition of the loop principle equipment for sizing, loop capacity and flow, the primary and secondary loop pumps, together with the distribution losses and oversizing factor for the heat transfer loop.

Distribution Losses

Enter the heat transfer loop distribution losses—i.e., the loss due to distribution of heating or cooling from the heating or cooling plant to point of use—as a percentage of heating or cooling demand. The loss entered here does not accrue to the conditioned spaces within the building. Rather, this heat is assumed to be lost either directly or indirectly to the outdoor environment.

|

Warning Limits (%)

|

0.0 to 20.0

|

|

Error Limits (%)

|

0.0 to 75.0

|

Oversizing Factor

Following system-level autosizing, the factor by which the heating or cooling plant equipment size is increased relative to the peak value occurring during the sizing run.

Principal equipment for sizing

Select the principle equipment for sizing, both for heating/heat acquisition and for cooling/heat rejection. To ensure there is always at least one device available to add required heat the heat transfer loop and to reject excess heat from the loop, a principle device for heating and cooling must be selected. This selection will, in turn, force at least one device to be defined for each of these roles.

There are three options for the principle heating device:

· Heating equipment set

· Water-source heat exchanger

· Air-to-water heat pump.

There are three options for the principle cooling device:

· Cooling tower/Fluid cooler

· Water-source heat exchanger

Except for the case of the Override checkbox beside the Current loop capacities (see below in the loop capacity section) is ticked, the capacities of the principal devices are the basis for the Current loop capacities and loop flow rate derivation. In other words, when the Override checkbox is not ticked, the Current loop capacities (heating and cooling) are dynamic copies of the capacities of the principal devices, and these may or may not have been updated by autosizing.

When the Override checkbox is ticked, the corresponding Current loop capacity becomes an input field, which allows values for Loop heating capacity or Loop cooling capacity to be overridden by a manual edit. Once overridden, the Current loop capacities, and hence the loop flow rate, are decoupled from the capacities of the principle device(s).

Tip: After completing a system sizing with one principle device selected, ticking the Override checkbox and switching the principle device from the pre-sizing selection to another one provides the opportunity to turn off the pre-sizing principle device in further simulations.

When a Heating equipment set is the principal heating device, capacity is given by the sum of the design heating capacities for equipment with nonzero sequencing rank in the rightmost column of the sequencing table in the Heating equipment set sub-tab of the Heat acquisition tab.

Whether or not an individual heating or cooling device on the loop will be autosized after a system sizing run, regardless of principle or non-principle status for sizing, depends on the status of its Autosize checkbox (see below). If the Autosize… checkbox for an individual device is ticked, its capacity will be updated after autosizing. Otherwise, its capacity will remain at the pre-sizing value.

If an individual device is designated as the Principle equipment for sizing, and its Autosize checkbox is ticked, then upon autosizing the peak Heat transfer loop heating or cooling capacity determined by autosizing will be used directly to update the capacity of this individual device. In other words, a principle device with its Autosize checkbox ticked will always get 100% of the autosized loop heating or cooling capacity, after consideration of the oversizing factor.

If an individual device is not the current principle device for sizing, and its Autosize checkbox is ticked, then upon autosizing the peak Heat transfer loop heating or cooling capacity determined by autosizing will be multiplied by its Percent of autosized loop heating or cooling capacity (see below) to determine its capacity. The resultant capacity will then be used to update the capacity of this individual device. In other words, a non-principle device with its Autosize checkbox ticked will get a percentage of the autosized loop heating or cooling capacity as specified by its Percent of autosized loop heating or cooling capacity, after consideration of the oversizing factor. In this case, the capacity fraction assigned to the non-principle device is not subtracted from the loop heating or cooling capacity.

Also, for a non-principle device with its Autosize checkbox ticked, once the heat transfer loop has been sized, edits made in its Percent of autosized loop heating or cooling capacity (%) field will lead to automatic dynamic updating of its capacity, based on the autosized loop heating or cooling capacity.

Loop capacity and flow

The Autosized loop capacities (for heating and cooling) are un-editable fields, which are initialized to zero and subsequently display the results from the most recent system auto-sizing analysis.

When the ‘Override’ checkbox besides the Current loop capacities is not ticked, the Current loop capacities (heating and cooling) are dynamic copies of the capacities of the principal devices (which may or may not have been updated by auto-sizing).

Ticking the ‘Override’ checkbox allows the Current value of the Loop heating or cooling capacity to be overridden by a manual edit (otherwise all these values are un-editable).

When the ‘Override’ box is ticked, after autosizing, the Current value of the associated capacity remains at the user-specified value. This value is not dynamically linked to the principle equipment sizes.

Loop flow rate is derived dynamically from the Current loop capacity values, taken together with loop temperature delta-T parameters specified in the ‘Temperature control’ tab. The loop flow rate feeds into dynamic parameter derivations for certain components on the loop (cooling tower, fluid cooler, water-source heat exchanger, etc.).

Capacities for individual heating and cooling devices can be edited manually, overriding autosized values for the equipment. In the case of principal equipment for sizing, when the ‘Override’ box is not ticked, user edits made in the principal equipment capacity will feed back to the Current value of Loop capacities. This may cause a change to Loop flow rate, which may in turn cause changes to dynamically derived parameters for other devices on the loop.

Loop Configuration

Select the loop configuration. Two options are offered: Primary-only and Primary-Secondary.

Primary Circuit Specific Pump Power at Rated Speed

Enter the primary circuit specific pump power at rated speed, expressed in W/(l/s) in SI units (or W/gpm in IP units).

If the ‘loop configuration’ is selected as Primary-only:

Primary circuit pump power will be calculated on the basis of variable flow, subject to the constraint that the pump will start cycling below the minimum flow rate it permits. The operating pump power will be based on its design pump power modified by the pump power curve. Its design pump power is calculated as the specific pump power multiplied by the design water flow rate. The default value for the specific pump power in this case is the total specific pump power (19 W/gpm) as specified in ASHRAE 90.1 G3.1.3.5.

The required variable flow featured in the pump power curve is calculated as the summation of required flow from all components (WAHPs) served by the heat transfer loop, subject to the minimum flow the pump permits. Required loop water flow rates for WAHPs vary in proportion to their heat rejection or heat acquisition loads.

If the ‘loop configuration’ is selected as Primary-Secondary:

Primary circuit pump power will be calculated on the basis of constant flow (when it operates). The model will be based on a specific pump power parameter, with a default value of 3.8 W/gpm. The default value is based on the total specific pump power (19 W/gpm) as specified in ASHRAE 90.1 G3.1.3.5 and assuming a 20:80 split between the primary and secondary circuits.

The primary circuit loop flow rate will be calculated from the Current loop capacity values, taken together with loop temperature delta-T parameters specified in the ‘Temperature control’ tab.

Primary Circuit Pump Heat Gain to Heat Transfer Loop (fraction)

Enter the primary circuit pump heat gain to heat transfer loop, which is the fraction of the motor power that ends up in the loop water. Its value is multiplied by the primary circuit pump power to get the primary circuit pump heat gain, which is added to the loop cooling load or deducted from the loop heating load.

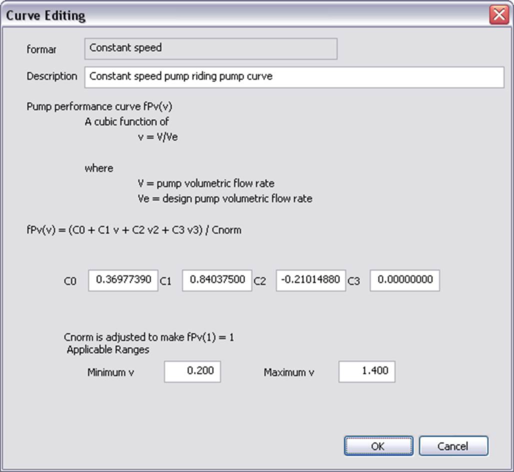

Primary Circuit Pump Power Curve, fPv(v)

This field is only active when the ‘loop configuration’ is selected as Primary-only.

If this field is active:

This is the primary circuit pump power curve currently selected. Use the Select button to select the appropriate curve from the system database. Use the Edit button to edit the curve parameters if you like. The Edit button will pop up a dialog displaying the formula and parameters of the curve, allowing the curve parameters to be edited. You are allowed to edit the curve coefficients, in addition to the applicable ranges of the curve independent variables. When editing the curve parameters, it is important that you understand the meaning of the curve and its usage in the model algorithm.

Also be careful that the edited curve has reasonable applicable ranges for the independent variables. A performance curve is only valid within its applicable ranges. In the case the independent variables are out of the applicable ranges you set, the variable limits (maximum or minimum) you specified in the input will be applied.

The primary circuit pump power curve f Pv (v) is a cubic function of

v = V/V e

where

V = pump volumetric flow rate.

V e = design pump volumetric flow rate.

And:

f Pv (v) = (C 0 + C 1 v + C 2 v 2 + C 3 v 3 ) / C norm

where

C 0 , C 1 , C 2 and C 3 are the curve coefficients

C norm is adjusted (by the program) to make f Pv (1) = 1

The primary circuit pump power curve is evaluated for each iteration of the heat transfer loop, for each time step during the simulation. The curve value is multiplied by the design primary pump power to get the operating primary pump power of the current time step, for the current fraction of pump volumetric flow rate. The curve should have a value of 1.0 when the operating pump volumetric flow rate equals rated pump volumetric flow rate (v = 1.0).

Figure 3 - 38 : Edit dialog for the primary circuit pump power curve (values for constant-speed pump are shown)

Secondary Circuit Specific Pump Power at Rated Speed

This field is only active when the ‘loop configuration’ is selected as Primary-Secondary.

If this field is active:

Enter the secondary circuit specific pump power at rated speed, expressed in W/(l/s) in SI units (or W/gpm in IP units). The default value (15.2 W/gpm) is based on the total specific pump power (19 W/gpm) as specified in ASHRAE 90.1 G3.1.3.5 and assuming a 20:80 split between the primary and secondary circuits.

Secondary circuit pump power will be calculated on the basis of variable flow, subject to the constraint that the pump will start cycling below the minimum flow rate it permits. The operating pump power will be based on its design pump power modified by the pump power curve.

Its design pump power is calculated as the specific pump power multiplied by the design loop flow rate. The design secondary circuit loop flow rate is assumed equal to the design primary circuit loop flow rate, which is calculated from the Current loop capacity values, taken together with loop temperature delta-T parameters specified in the ‘Temperature control’ tab.

The required variable flow featured in the pump power curve is calculated as the summation of required flow from all components (WAHPs) served by the heat transfer loop, subject to the minimum flow the pump permits. Required loop flow rates for WAHPs vary in proportion to their heat rejection or heat acquisition loads.

Secondary Circuit Pump Heat Gain to Heat Transfer Loop (fraction)

This field is only active when the ‘loop configuration’ is selected as Primary-Secondary.

If this field is active:

Enter the secondary circuit pump heat gain to heat transfer loop, which is the fraction of the motor power that ends up in the loop water. Its value is multiplied by the secondary circuit pump power to get the secondary circuit pump heat gain, which is added to the loop cooling load or deducted from the loop heating load.

Secondary Circuit Pump Power Curve, fPv(v)

This field is only active when the ‘loop configuration’ is selected as Primary-Secondary.

If this field is active:

This is the secondary circuit pump power curve currently selected. Use the Select button to select the appropriate curve from the system database. Use the Edit button to edit the curve parameters if you like. The Edit button will pop up a dialog displaying the formula and parameters of the curve, allowing the curve parameters to be edited. You are allowed to edit the curve coefficients, in addition to the applicable ranges of the curve independent variables. When editing the curve parameters, it is important that you understand the meaning of the curve and its usage in the model algorithm.

Also be careful that the edited curve has reasonable applicable ranges for the independent variables. A performance curve is only valid within its applicable ranges. In the case the independent variables are out of the applicable ranges you set, the variable limits (maximum or minimum) you specified in the input will be applied.

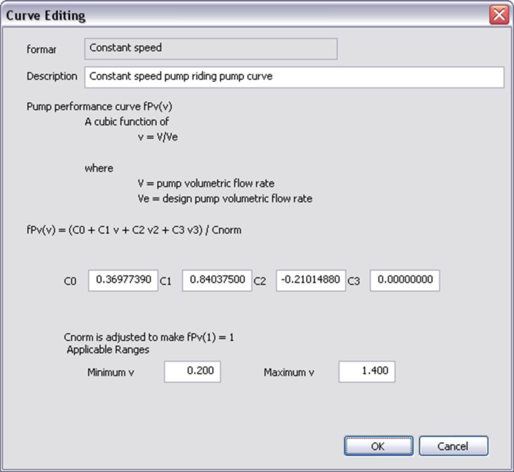

The secondary circuit hot water pump power curve f Pv (v) is a cubic function of

v = V/V e

where

V = pump volumetric flow rate.

V e = design pump volumetric flow rate.

and

f Pv (v) = (C 0 + C 1 v + C 2 v 2 + C 3 v 3 ) / C norm

where

C 0 , C 1 , C 2 and C 3 are the curve coefficients

C norm is adjusted (by the program) to make f Pv (1) = 1

The secondary circuit pump power curve is evaluated for each iteration of the heat transfer loop, for each time step during the simulation. The curve value is multiplied by the design secondary pump power to get the operating secondary pump power of the current time step, for the current fraction of pump volumetric flow rate. The curve should have a value of 1.0 when the operating pump volumetric flow rate equals rated pump volumetric flow rate (v = 1.0).

Figure 3 - 39 : Edit dialog for the secondary circuit pump power curve (values for constant-speed pump are shown)

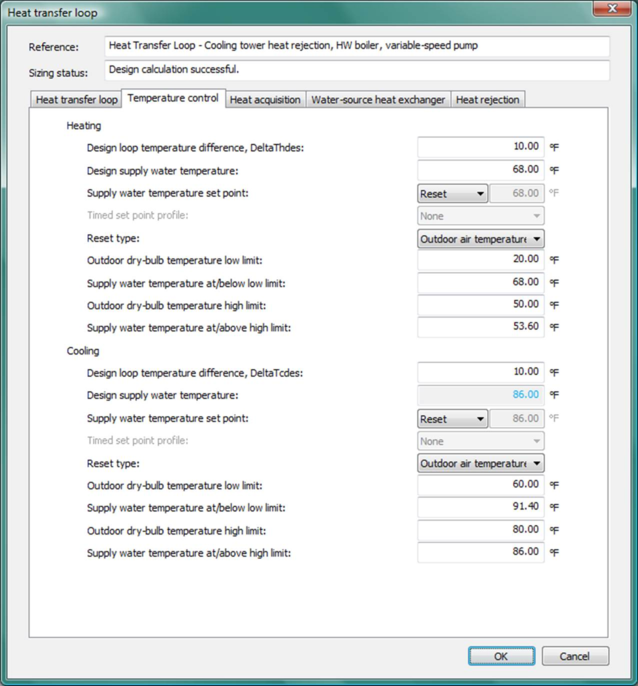

Temperature control tab

The Temperature control tab provides inputs for the heat transfer loop temperature controls. There are two parallel sets of temperature control parameters provided in this tab: one set for heating, one set for cooling. The descriptions below for each of these temperature control parameters apply to both heating and cooling temperature controls.

Figure 3 - 40 : Temperature control tab on Heat transfer loop dialog.

Design Loop Temperature Difference, DeltaThdes & DeltaTcdes

Enter the design loop temperature difference for heating and cooling, i.e., the difference between the design loop supply water temperature and return water temperature.

Design Supply Water Temperature

For heating, the design loop supply water temperature may be either an input field or a derived parameter (un-editable field with a grey background), depending on the currently selected heating principle equipment for sizing (in the Heat transfer loop tab). If this is an input field, enter the desired design loop supply water temperature for heating. If this is a derived parameter, then the heating design loop supply water temperature is determined by parameter inputs for the currently selected heating principle equipment for sizing, and does not need to be entered in the Temperature control tab.

For cooling, the design loop supply water temperature currently is always a derived parameter (un-editable field with a grey background), and does not need to be entered in the Temperature control tab. It is determined by parameter inputs for the currently selected cooling principle equipment for sizing, which may be either Cooling tower/Fluid cooler or WSHX.

The default values for heating and cooling design supply water temperatures are taken as the rated WAHP entering fluid temperatures from ANSI/ARI/ASHRAE ISO Standard 13256-1: 1998.

Supply Water Temperature Set Point

Three options are available for heating and cooling supply water temperature set point: Constant, Profiled, or Reset.

Whichever option is selected, to avoid the heating and cooling set point compete each other on the loop temperature control at the same time step during a simulation, please ensure that the heating supply water temperature set point is not higher than the cooling supply water temperature set point at the same time step during a simulation. Otherwise, an error will be reported and the simulation will not be able to proceed.

The software provides a check on this when it is possible, i.e., when both heating and cooling set points are specified as Constant. For all other cases, it is your responsibility to avoid the heating and cooling set point compete each other on the loop temperature control at the same time step during a simulation.

Constant Supply Water Temperature Set Point

When Constant is selected for heating and cooling supply water temperature set point, enter the desired constant heating and cooling loop supply water temperature set point.

Timed Supply Water Temperature Set Point Profile

When Profiled is selected for heating and cooling supply water temperature set point, select the absolute profile to be applied to the loop supply water temperature set point, which are defined through the APPro facility (the Profiles Database).

Supply Water Temperature Reset Type

When Reset is selected for heating and cooling supply water temperature set point, select the supply water temperature reset type. Currently only one option is provided: Outdoor air temperature reset . When Outdoor air temperature reset type is selected, which is the default, you also need to specify four more reset parameters:

· Outdoor dry-bulb temperature low limit

· Supply water temperature at or below low limit

· Outdoor dry-bulb temperature high limit

· Supply water temperature at or above high limit

Outdoor Dry-bulb Temperature Low Limit

When heating or cooling supply water temperature reset type is selected as Outdoor air temperature reset, enter the outdoor dry-bulb temperature low limit to be used by the reset.

Supply Water Temperature at or below Low Limit

When heating or cooling supply water temperature reset type is selected as Outdoor air temperature reset, enter supply water temperature at or below the outdoor dry-bulb temperature low limit, to be used by the reset.

Outdoor Dry-Bulb Temperature High Limit

When heating or cooling supply water temperature reset type is selected as Outdoor air temperature reset, enter the outdoor dry-bulb temperature high limit to be used by the reset.

Supply Water Temperature at or above High Limit

When heating or cooling supply water temperature reset type is selected as Outdoor air temperature reset, enter the supply water temperature at or above the outdoor dry-bulb temperature high limit, to be used by the reset.

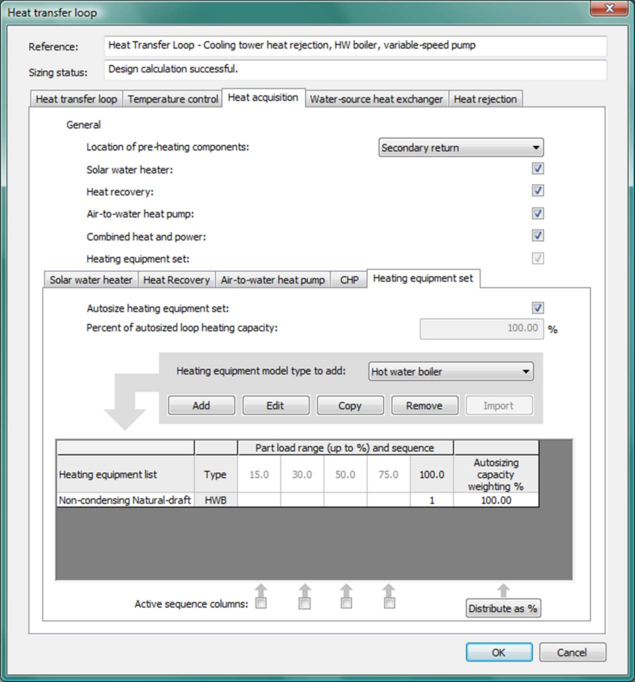

Heat acquisition tab

The Heat acquisition tab manages information used for all possible heating devices (SWH, CHR, AWHP, CHP, heating equipment set) on the loop, except for the WSHX, which can be used as both heating and cooling source and is presented in its own separate tab. For each of the possible heating devices presented in this tab, there is a corresponding checkbox and an associated sub-tab. Ticking or un-ticking a checkbox will enable or disable the associated sub-tab. The hard-wired sequence for heat acquisition on a heat transfer loops is SWH à WSHX à CHR à AWHP à CHP à Heating equipment set .

Figure 3 - 41 : Heat acquisition tab on Heat transfer loop dialog (shown with the Heating equipment set sub-tab selected).

Location of Pre-heating Components

Select the Location of pre-heating components on the heat transfer loop. Currently only one option is provided: Secondary return.

Solar water heater

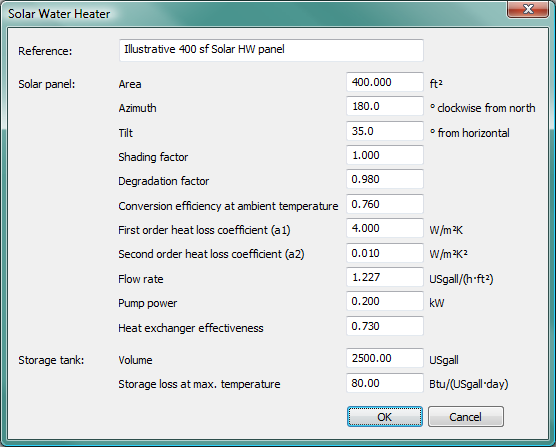

Solar water heater can be used as a pre-heating device on a heat transfer loop. When present, the solar water heater will be the first-loaded device to cover heating load imposed on the heat transfer loop. Solar water heater on a heat transfer loop is modeled and functions in exactly the same manner as the Solar water heater on the hot water loop (see section 3.3.5 Solar Water Heater).

Figure 3 - 42 : Solar water heater dialog with illustrative inputs.

Solar water heater checkbox

Tick this checkbox to specify a solar water heater as a pre-heating device on the heat transfer loop. Ticking or un-ticking this checkbox will enable or disable the associated Solar water heater sub-tab below.

Solar water heater reference

This displays the Reference name of the solar water heater associated with this heat transfer loop. It is not editable directly in the HTL dialog and should be edited in the solar water heater dialog, which is opened by clicking the ‘Edit’ button to the right of this field.

Heat recovery

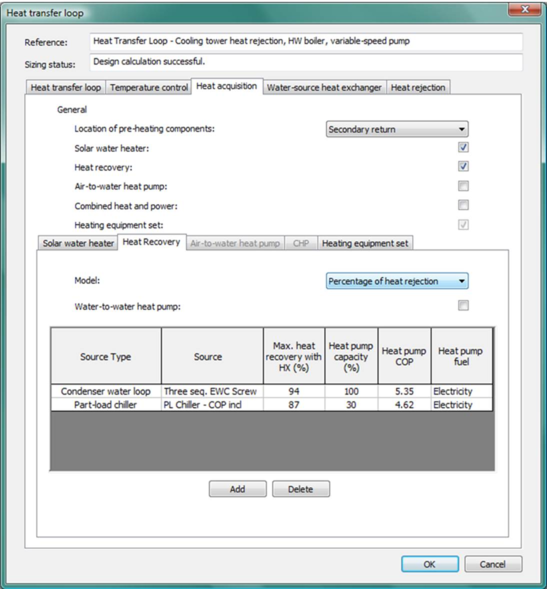

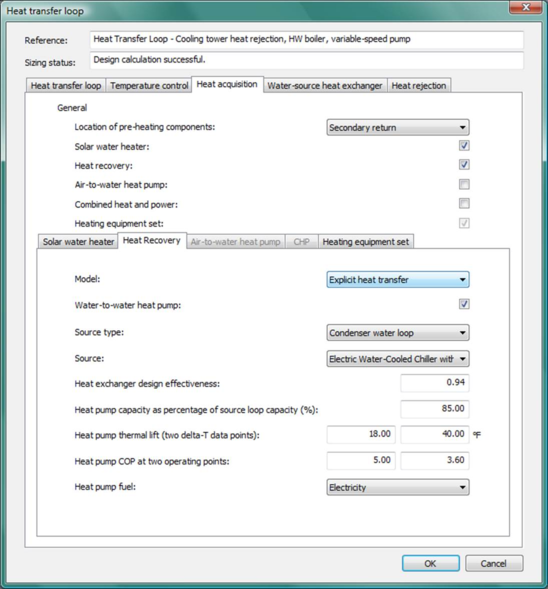

Heat recovery, when enabled within the Heat transfer loop dialog, serves heat acquisition loads ahead after any solar water heating and/or water-source heat exchanger. The hard-wired sequence for heat acquisition on a heat transfer loops is SWH à WSHX à CHR à AWHP à CHP à Heating equipment set . The heat recovery can be modeled as either a heat exchanger or water-to-water heat pump between loops. Most often, but not always, the recovered heat is from a condenser water loop for cooling equipment, and in that case referred to as condenser heat recovery (CHR).

There are two heat exchanger and water-water heat pump (WWHP) model options for heat recovery when the recipient is a Hot water loop: a simple fixed-percentage effectiveness heat exchanger and fixed-COP heat pump or an explicit model with heat exchanger effectiveness and heat pump COP varying according to the loop water temperatures.

-

Percentage of heat rejection heat-exchanger model

This simple heat-exchanger model is essentially the same as the heat recovery model provided in pre-v6.5 versions. It models the heat recovery as a simple percentage of the source heat rejection. The percentage represents a fixed heat-exchanger effectiveness.

-

Fixed-COP water-source heat pump model

The temperature for the recovered heat can be upgraded with a water-to-water or water-source heat pump (WSHP)—e.g., from 90°F to 140°F. This would typically be used when serving space-heating loads such as direct (DX-based) heating of supply air or hot water for heating coils and baseboard heaters that require higher temperatures than normally available via a simple heat exchanger on the condenser water loop. The Percentage of heat rejection model can be used regardless of whether there is an explicit modeling of the loop water temperatures on the heat recovery source and recipient sides.

Explicit heat transfer :

-

This option models the heat transfer between the heat recovery source and recipient loops using an explicit water-to-water heat exchanger, which modulates the heat exchanger effectiveness for off-design temperature differences across the heat exchanger.

-

Variable-COP water-source heat pump model

In the explicit heat transfer model, the water-to-water heat pump (WWHP) used to upgrade recovered heat modulates COP in response to the temperature difference or “thermal lift” between the heat recovery source loop and the heat recovery recipient loop at each simulation time step. This relatively simple model uses linear interpolation to vary the COP between two user-input COP values corresponding to two heat pump operation points (low & high thermal lift). The Explicit heat transfer model can be used only when there is an explicit modeling of the loop water temperatures on the heat recovery source and recipient sides.

Capacity for the Heat Recovery WWHP is now limited to a user-specified percentage of the heat recovery source capacity, whereas in pre-v6.5 versions WWHP capacity was a percentage of the instantaneous load on the source. This revised limit has been introduced in both of the WWHP models described above in order to provide a more realistic basis for the capacity. This avoids recovering more heat with the WWHP than would be possible (or desirable) in practice. Without this constraint the WWHP could entirely displace the boilers on a HWL, which might not be what the user intends or expects.

Heat recovery sources and recipients

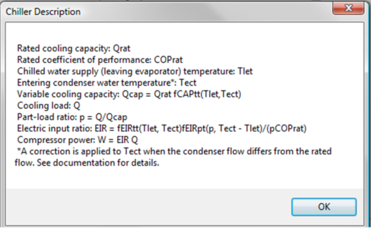

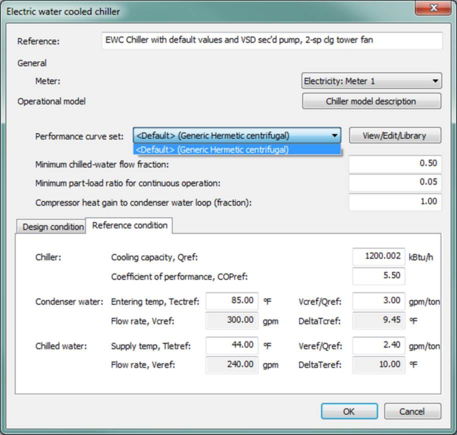

All heat recovery data are now displayed, edited, and stored on the recipient side ( Chiller Model Description

Clicking this button provides a summary of electric water-cooled chiller model variables as shown below:

Figure 3-97: Electric water-cooled chiller model description

Figure 3-98 and Figure 3-17 below).

Heat recovery sources can be either a part-load-curve “chiller” model (which may represent something other than a water-cooled chiller) or a condenser water loop serving one or more electric water-cooled chillers. Future versions will expand on the range of possible sources, for example, allowing the heat-transfer loop to be selected as a source. Heat recovery recipients can be a generic heat source, a hot water loop, or a heat transfer loop.

When the Percentage of heat rejection model is used, there can be multiple heat recovery sources linked to one recipient. This is among the reasons that the sources are now specified in the recipient dialog. Source types can be any combination of condenser water loops and/or part-load curve chiller models. Each heat recovery source can be linked to just one heat recipient.

When the Explicit heat transfer model is used, there can be only one heat recovery source linked to a given recipient loop, and the source type is limited to condenser water loops.

The heat recovery recipient is displayed on the source side (Heat recovery sub-tab within the Heat Rejection tab of the Chilled water loop dialog and in the Part-load curve chiller model dialog) for user’s information only. Each heat recovery source can be linked to only one heat recovery recipient.

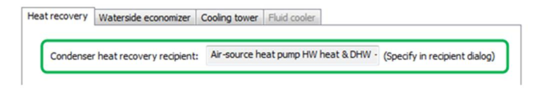

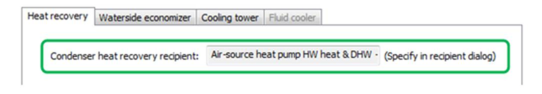

Figure 3 - 43 : Heat Recovery sub-tab on the Heat acquisition tab within the Heat transfer loop dialog (top) using the Percentage of heat rejection model with water-to-water heat pump and illustrative inputs for source, percentage heat recovery, and WWHP performance. Also shown (below the Hot water loop dialog), the Condenser heat recovery recipient designation is displayed within the Heat rejection tab of the Chilled water loop dialog.

Figure 3 - 44 : Heat Recovery tab within the Heat transfer loop dialog (top) using the Explicit heat transfer model with water-to-water heat pump and illustrative inputs for source, heat exchanger effectiveness, and WWHP performance. Also shown (below the Hot water loop dialog), the Condenser heat recovery recipient designation is displayed within the Heat rejection tab of the Chilled water loop dialog.

Heat recovery checkbox

Tick this checkbox to specify heat recovery as a heat source on the heat transfer loop. Ticking or un-ticking this checkbox will enable or disable the associated heat recovery sub-tab below.

Heat recovery model

Choose the desired heat recovery model type. Two model types are provided: Percentage of heat rejection and Explicit heat transfer.

If Percentage of heat rejection is selected, you will be able to specify multiple heat recovery sources contributing to the same hot water loop (the heat recovery recipient), listed in a source table below, together with other parameters required by the Percentage of heat rejection model. For each heat recovery source row in the table, these column fields are displayed: Source type, Source, Max. heat recovery with HX (%, as percentage of source loop load), Heat pump capacity (%, as percentage of source loop capacity), Heat pump COP, and Heat pump fuel. In this case, a heat recovery source can be added or removed using the Add or Delete button below the source table. Double clicking any active cell within the source table provides editing access to that specific cell.

If Explicit heat transfer is selected, you will be able to specify only one heat recovery source contributing to the hot water loop (the heat recovery recipient), together with other parameters required by the Explicit heat transfer model.

Water-to-water heat pump checkbox

The heat recovered from the heat recovery source(s) may be upgraded using a water-to-water heat pump (See additional explanation above). Specify this mode of operation by ticking the Water-to-water heat pump checkbox.

Source type

Choose the heat recovery source type for a particular source.

For the Percentage of heat rejection model, Source type is listed in the first column of the source table. Double clicking a cell in this column allows you to choose the source type from two options: Condenser water loop or Part load chiller.

For the Explicit heat transfer model, Source type is selected from the Source type combo box, currently with one available option: Condenser water loop.

When source type is Condenser water loop, this is referring to a condenser water loop associated with a currently defined chilled water loop.

When source type is Part load chiller, this is referring to any currently defined part load chiller either on a chilled water loop or separately defined as a Generic cooling source.

Source

Choose the heat recovery source name for a particular source.

For the Percentage of heat rejection model, Source is listed in the second column of the source table. Double clicking a cell in this column allows you to choose the source from a drop-down list of available sources currently defined in the HVAC system file.

For the Explicit heat transfer model, use the Source drop-down list on the right hand side of the dialog to select from available sources currently defined in the HVAC system file.

Note that for both heat recovery models, only the current available sources defined in the HVAC file will be included in the drop-down list:

· If the selected Source type is Condenser water loop, ‘available’ means the listed chilled water loop has a condenser water loop (Condenser water loop box on Heat rejection tab is ticked) that has not been specified as a heat recovery source for any other heat recovery recipient.

· If the selected Source type is Part-load chiller, ‘available’ means the defined part-load chiller has not been specified a heat recovery source for any other heat recovery recipient.

On switching the model option from Percentage of heat rejection to Explicit heat transfer, no more than one source will remain active and displayed (and this must not be a part load curve chiller). If there are multiple sources specified prior to the switch and these include more than one valid source for the Explicit heat transfer option, then the first valid source for the Explicit heat transfer option will remain; other specified sources will be removed. If prior to the switch, there are only part load curve chillers specified as sources, then upon switching the Source combo list will be set to <None>.

For a specified heat recovery source, its recipient will be displayed in the corresponding source dialog for user’s information only.

Max. heat recovery with HX (%)

This parameter is only required by the Percentage of heat rejection model. When Percentage of heat rejection model is used, this field (in the 3rd column of the source table) represents the percentage of the source heat rejection (from either a condenser water loop or a part load chiller) that is subject to heat recovery using a heat exchanger.

In this case, the amount of heat recovered at any given time is given by:

Where, Ql is the load on the electric water-cooled chiller(s) if the heat recovery source is a condenser water loop (or the load on the part load curve chiller if the source is from a part load chiller), Qc is the compressor power for the chiller(s) and p is heat recovery percentage.

Heat exchanger design effectiveness

This parameter is only required by the Explicit heat transfer model. When Explicit heat transfer model is used, it represents the design effectiveness of the water-to-water heat exchanger used for heat recovery purpose.

Heat pump capacity (%)

This field is only enabled when the Water-to-water heat pump checkbox is ticked, i.e., when a water-to-water heat pump is used to upgrade the heat recovered from the source(s). When active, enter the capacity for the desired water-to-water heat pump, as a percentage of the source loop capacity. This is used to limit the capacity of the water-to-water heat pump. When heat recovery source is a condenser water loop: the source loop capacity is the cooling tower or fluid cooler capacity (the condenser water loop capacity). When heat recovery source is a part load chiller: the source loop capacity is the part load chiller heat rejection capacity.

For the Percentage of heat rejection model, heat pump capacity is listed in the 4th column of the source table. Double clicking a cell in this column allows you to manually edit its value.

For the Explicit heat transfer model, heat pump capacity can be edited in the named field.

Heat pump COP

This field is only enabled when the Water-to-water heat pump checkbox is ticked, i.e., when a water-to-water heat pump is used to upgrade the heat recovered from the source(s). When active, enter the COP(s) for the desired water-to-water heat pump.

For the Percentage of heat rejection model, heat pump COP is listed in the 5th column of the source table. Double clicking a cell in this column allows you to manually edit its value, which should normally be the COP for this equipment when the source loop and recipient loop are at design temperatures; however, this may differ for some system designs. In this case, the specified COP is applied as a constant for a WWHP coupled to a specific heat recovery source during simulation.

For the Explicit heat transfer model, heat pump COP can be edited in the named field at two operating points corresponding to the two Heat pump thermal lifts (two delta-T data points) that you could specify (see below). In this case, instead of using a constant COP for the WWHP, the WWHP COP will be made responsive to the thermal lift between the heat recovery source loop and the heat recovery recipient loop during the simulation: linear interpolation will be applied to 1/COP using the two heat pump COP values corresponding to the two specified operation points (low, high).

Heat pump thermal lift (two delta-T data points)

This field is only required by the Explicit heat transfer model, and is only enabled when the Water-to-water heat pump checkbox is ticked, i.e., when a water-to-water heat pump is used to upgrade the heat recovered from the source(s). When active, enter the two heat pump thermal lifts (two delta-T data points: low, high) for the desired water-to-water heat pump. The thermal lift of the WWHP is the difference between the heat recovery source-side loop temperature before heat pump heat recovery and the recipient-side loop water temperature after heat recovery (which will ideally be the target supply water temperature of the recipient loop). During simulation, linear interpolation will be applied to 1/COP using the two heat pump COP values (see above) corresponding to the two specified thermal lifts (low, high).

Heat pump fuel

This field is only enabled when the Water-to-water heat pump checkbox is ticked, i.e., when a water-to-water heat pump is used to upgrade the heat recovered from the source(s). When active, select the fuel, type of energy source, or energy end-use category for the water-to-water heat pump. For scratch-built systems, this will normally be Electricity and for pre-defined systems this is set to Heating (electricity), which is an end-use designation for the ASHRAE 90.1 Performance Rating Method reports.

For the Percentage of heat rejection model, heat pump fuel is listed in the last column of the source table. Double clicking a cell in this column allows you to choose the heat pump fuel for the desired water-to-water heat pump coupled to a specific heat recovery source.

For the Explicit heat transfer model, heat pump fuel can be selected through the named field.

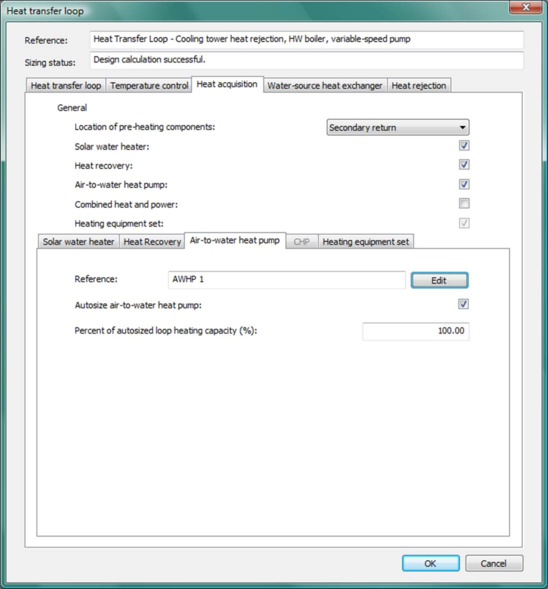

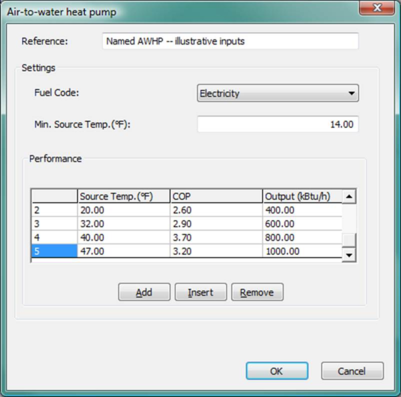

Air-to-water heat pump

An Air-to-water heat pump (AWHP) can be used as a heating device on the heat transfer loop. When present, the Air-to-water heat pump will be the first in line to meet loop heating load. The following loading sequence is pre-set for all heat transfer loops: SWH à WSHX à CHR à AWHP à CHP à Heating equipment set .

Figure 3 - 45 : Heat acquisition tab on Heat transfer loop dialog (shown with the Air-to-water heat pump sub-tab selected).

Air-to-water heat pump checkbox

Tick this checkbox to specify an Air-to-water heat pump as a heating device on the heat transfer loop. Ticking or un-ticking this checkbox will enable or disable the associated Air-to-water heat pump sub-tab below.

If the Air-to-water heat pump is selected as the heating principal equipment for sizing, this checkbox is automatically ticked and is not allowed to be un-ticked.

The input parameters for Air-to-water heat pumps are described in section 3.6.2

Air-to-water heat pump reference

This displays the reference name of the Air-to-water heat pump associated with this heat transfer loop. It is not editable directly in the HTL dialog and should be edited in the Air-to-water heat pump dialog, which is opened by clicking the Edit button to the right of this field. The input parameters for Air-to-water heat pumps are described in section 3.6.2

The Edit button opens the Air-to-water heat pump dialog.

Figure 3 - 46 : Air-to-water heat pump dialog with illustrative inputs (described in section 3.6.2 ).

Autosize air-to-water heat pump

Tick this checkbox to autosize the associated Air-to-water heat pump during a system sizing run.

When this box is ticked:

If the air-to-water heat pump is selected as the heating principal equipment for sizing, then the peak Heat transfer loop heating capacity determined by autosizing will be used directly to update the part-load capacity (output) values in the Air-to-water heat pump dialog. In other words, the heat pump will get 100% of the autosized loop heating capacity, after consideration of the oversizing factor.

If the air-to-water heat pump is not selected as the heating principal equipment for sizing, then the peak Heat transfer loop heating capacity determined by autosizing will be multiplied by the Percent of autosized loop heating capacity (%) (see below) to determine the Air-to-water heat pump capacity. The resultant maximum heat pump capacity value will then be used to update the part-load capacity (output) values in the Air-to-water heat pump dialog. In other words, the heat pump will get a percentage of the autosized loop heating capacity as specified by its Percent of autosized loop heating capacity (%), after consideration of the oversizing factor. Note that in this case, the capacity fraction assigned to the heat pump is not subtracted from the heat transfer loop heating capacity. In other words, the air-to-water heat pump size will not influence the size of the heat transfer loop.

The capacity updating process for an Air-to-water heat pump after autosizing will reset the capacity (output) value in the bottom row and proportionally adjust all other part-load capacity values to maintain their relationships as load fractions.

Percent of autosized loop heating capacity (%)

This field is only enabled when the air-to-water heat pump is not selected as the current heating principal equipment for sizing and its ‘Autosize air-to-water heat pump’ checkbox (see above) is ticked.

When this field is enabled, during a system sizing run, the autosized loop heating capacity will be multiplied by the value in this field to get the heat pump capacity. The resultant heat pump capacity will then be used to update the air-to-water heat pump capacity in the normal way (re-set the value in the bottom row and adjust all other to maintain proportional relationships in the heat pump data lines).

Once the heat transfer loop has been sized, edits made in this field will lead to automatic dynamic updating of the heat pump capacity and adjusting of all other data lines in the associated heat pump dialog, based on the autosized loop heating capacity.

Note that the capacity fraction assigned to the heat pump is not subtracted from the loop heating capacity. In other words, the Air-to-water heat pump size will not influence the Heat transfer loop sizing.

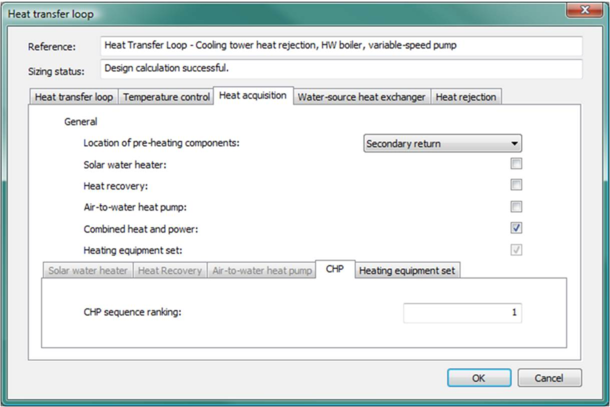

Combined heat and power

Heat available from a Combined heat and power (CHP) system can be used as a heat source on the heat transfer loop. When present, heat available from the CHP system will be used to cover loop heating load prior to engaging the Heating equipment set on the Heat transfer loop, according to the following loading sequence: SWH à WSHX à CHR à AWHP à CHP à Heating equipment set . A CHP system is defined within the CHP section of the Renewables dialog in the Apache Thermal view.

Figure 3 - 47 : Heat acquisition tab on Heat transfer loop dialog (shown with the CHP sub-tab selected).

Combined heat and power checkbox

Tick this checkbox to specify Combined heat and power (CHP) system as a heat source on the heat transfer loop. Ticking or un-ticking this checkbox will enable or disable the associated CHP sub-tab below.

CHP sequence ranking

CHP sequence ranking determines the sequence in which heat available from CHP are used to cover heating loads imposed on the specified heat sources. Heat sources (Generic, Hot water loop, or Heat transfer loop) with lower values of this parameter will receive available heat from CHP before those with higher values. The former will normally be the most efficient heat sources. If two ApacheHVAC heat sources have the same sequence ranking in this field, they will simultaneously receive available heat from the CHP system in Apache Thermal until either the loads are met or the CHP resource is fully utilized.

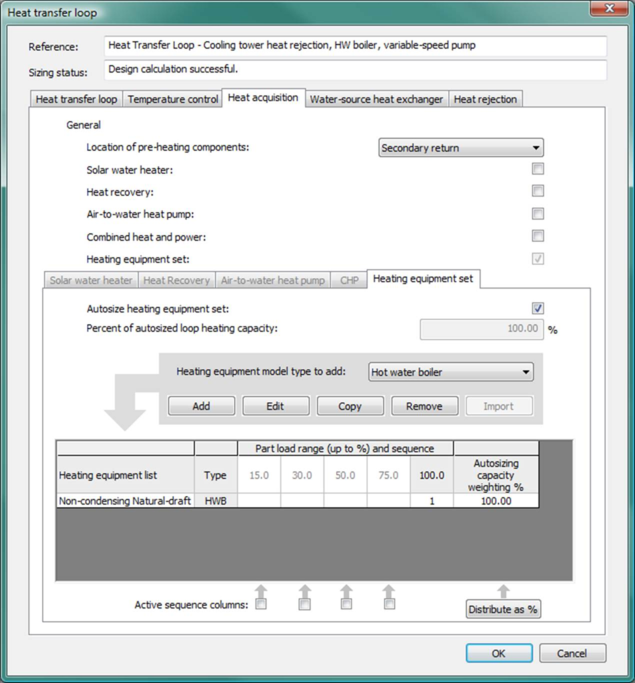

Heating Equipment Set

A Heating equipment set can be used as heat source on the heat transfer loop. When present, the Heating equipment set will be the last in line to meet loop heating load. The following loading sequence is pre-set for all heat transfer loops: SWH à WSHX à CHR à AWHP à CHP à Heating equipment set .

The Heating equipment set sub-tab, which is enabled by ticking the Heating equipment set checkbox, facilitates the definition of the heating equipment serving the heat transfer loop. Heating equipment can be added, edited, copied and removed from the existing heating equipment list (the first column of the sequencing table). Heating equipment can also be imported from an existing heat transfer loop using the Import button.

A heating equipment sequencing table is provided to set the order in which heating equipment are turned on within any particular load range and to set the relative weighting of autosized capacities. Tick boxes are provided to activate up to 5 load ranges for sequencing and the cells with white background can be edited by double clicking. The cells containing heating equipment names in the heating equipment list column provide access to editing individual heating equipment.

Figure 3 - 48 : Heat acquisition tab on Heat transfer loop dialog (shown with the Heating equipment set sub-tab selected).

Heating equipment set checkbox

Tick this checkbox to specify Heating equipment set as a heat source on the heat transfer loop. Ticking or un-ticking this checkbox will enable or disable the associated Heating equipment set sub-tab below.

If the Heating equipment set is selected as the heating principal equipment for sizing, this checkbox is automatically ticked and is not allowed to be un-ticked.

Autosize heating equipment set

Tick this checkbox to autosize the associated Heating equipment set during a system sizing run.

When this box is ticked:

If the Heating equipment set is selected as the heating principal equipment for sizing, then the peak Heat transfer loop heating capacity determined by autosizing will be used directly to update the capacity of the Heating equipment set. In other words, the Heating equipment set will get 100% of the autosized loop heating capacity, after consideration of the oversizing factor.

If the Heating equipment set is not selected as the heating principal equipment for sizing, then the peak Heat transfer loop heating capacity determined by autosizing will be multiplied by the Percent of autosized loop heating capacity (%) (see below) to determine and update the Heating equipment set capacity. In other words, the Heating equipment set will get a percentage of the autosized loop heating capacity as specified by its Percent of autosized loop heating capacity (%), after consideration of the oversizing factor. Note that in this case, the capacity fraction assigned to the Heating equipment set is not subtracted from the heat transfer loop heating capacity. In other words, the Heating equipment set size will not influence the size of the heat transfer loop.

The resultant Heating equipment set capacity value (from either of the above two cases) will then be used to update the capacities of individual heating equipment defined for the Heating equipment set. The capacities of individual heating equipment are derived by distributing the Heating equipment set capacity using capacity weightings specified for individual heating equipment.

Percent of autosized loop heating capacity (%)

This field is only enabled when the Heating equipment set is not selected as the current heating principal equipment for sizing and its ‘Autosize heating equipment set’ checkbox (see above) is ticked.

When this field is enabled, during a system sizing run, the autosized loop heating capacity will be multiplied by the value in this field to get the Heating equipment set capacity. The resultant Heating equipment set capacity will then be used to update the capacities of individual heating equipment defined for the Heating equipment set in the normal way (distributing the Heating equipment set capacity using capacity weightings specified for individual heating equipment).

Once the heat transfer loop has been sized, edits made in this field will lead to automatic dynamic updating of the Heating equipment set capacity and adjusting of capacities for individual heating equipment associated with this Heating equipment set, based on the autosized loop heating capacity.

Note that the capacity fraction assigned to the Heating equipment set is not subtracted from the loop heating capacity. In other words, the Heating equipment set size will not influence the Heat transfer loop sizing.

Heating Equipment Model Type to Add

This selection determines the type of heating equipment model to be added when clicking the Add button. Currently two model types are available: part load curve heating plant and hot water boiler.

The Heating equipment set can include any combination of two different heating equipment types:

· Hot water boiler: uses editable pre-defined curves and other standard inputs, such as efficiency at rated condition, supply temperature, flow rate, and parasitic loads

· Part load curve heating plant: flexible generic inputs entered in a matrix of load-dependent efficiency and parasitic power—i.e., a data grid with efficiency and pump/parasitic power set relative to maximum and part-load values; can represent any device used to heat water

Heating equipment List

The heating equipment list column lists the heating equipment in the Heating equipment set for the current Heat transfer loop. Up to 10 separate pieces of heating equipment can be listed and sequenced. To open the Edit dialog for any particular heating equipment, double-click a heating equipment name on the list or select a heating equipment item and click the Edit button.

Heating equipment Type

The heating equipment type column indicates the model type for each piece of equipment on the list. The types are determined when the heating equipment is added.

PLE = Part-load equipment

HWB = Hot-water boiler

Part Load Range (up to %)

The part load range (%) values can be edited, with the exception of the last value (100%). Up to five part-load ranges can be set. Apart from unused columns—those with no check in the box at the bottom of the column, and thus grayed-out values—part load range values must always increase from left to right.

Heating equipment Sequence Rank

Heating equipment sequence ranks are entered in the body of the table, for each heating equipment and for each part load range. These are integers in the range of 0 to 99 that determine the order in which heating equipment will be engaged during simulation. Within a specific part load range, heating equipment with lower sequence rank will be engaged first. At least one piece of heating equipment should have a nonzero sequencing rank in every column.

When multiple heating equipment are specified to have the same sequence rank for a part load range, they will be engaged simultaneously within that part load range and will share the loop load in proportion to their design capacities.

Within any range (except the last), if all the specified heating equipment are operating at maximum output, the sequencing moves to the next range.

Note: If the loop heating load exceeds the combined capacity of all heating sources available on the loop, any deficiency in overall heat transfer loop capacity will result in a deviation of the loop supply water temperature from the loop heating supply water temperature set point, thus providing feedback to the WAHPs served by the heat transfer loop. In other words, heating sources on a Heat transfer loop will always attempt to achieve the target supply water temperature. If the target supply water temperature cannot be reached, the WAHPs served must attempt to meet heating loads with cooler water.

The WAHPs served by the HTL will respond to the adjusted loop supply water temperature in its capacity and efficiency calculations, as the loop supply water temperature features as one of the independent variables in the WAHP performance curves.

Heating Equipment Autosizing Capacity Weighting

Heating equipment autosizing capacity weighting is a column of values indicating the relative proportion of the load that each piece of heating equipment will take during autosizing. If the rightmost sequence rank is zero for any heating equipment, the corresponding autosizing capacity weighting will be set automatically to zero. Any heating equipment with a zero autosizing capacity weighting will not be autosized. The Distribute as % button normalizes the autosizing capacity weightings so that they sum to 100. When all the autosizing weightings are zero the Distribute as % button is disabled. It is not obligatory to use the Distribute as % button, as the values will be normalized automatically when applied.

Active Sequence Columns

Under each part load range column of the heating equipment sequencing table (except the 100% column), there is a checkbox indicating the current status of the column. These checkboxes can be ticked only from right to left and un-ticked only from left to right.

When a check box is ticked, it will populate the column immediately above it with the data from the column to the right of it, thereby rendering the column immediately above it editable. The next checkbox for column immediately to the left of this checkbox will be enabled as well.

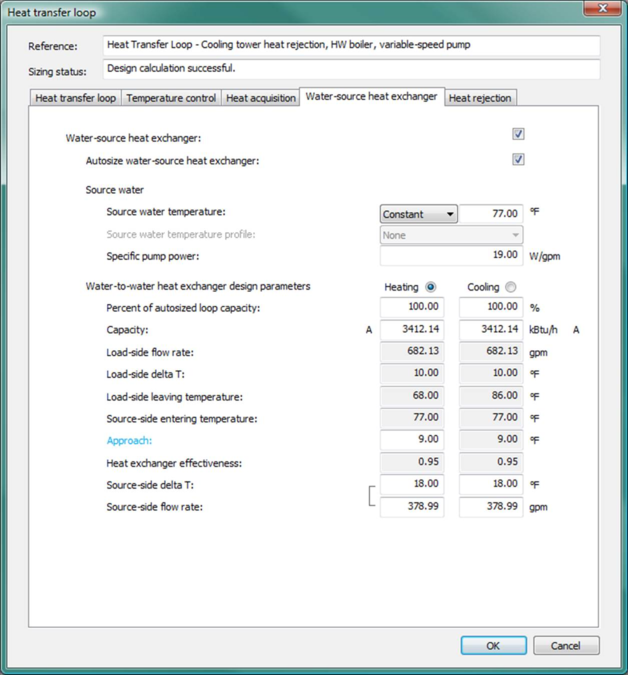

Water-source heat exchanger tab

The Water-source heat exchanger tab provides inputs for the water-source heat exchanger, which can be used as both heating and cooling source of the loop. When present, the water-source heat exchanger will be first in line to cover heating or cooling load imposed on the heat transfer loop, following the preset loading sequence for heating or cooling:

· Heating: SWH à WSHX à CHR à AWHP à CHP à Heating equipment set

· Cooling: WSHX à Cooling tower (or fluid cooler)

In addition to the source water parameters (in the Source water section), there are two sets of design parameters required for the water-source heat exchanger (in the Water-to-water heat exchanger design parameters section): one for heating and one for cooling.

Possible application for the water-source heat exchanger on the heat transfer loop is to connect it to an open water loop that draws water from a lake or well so that a ground-water system can be set up to serve WAHPs on the loop. Alternatively, the water-source heat exchanger can be connected to a closed loop utilizing a loop of plastic pipe that acts as a “geo-thermal heat exchanger”. However, please be reminded that the ground source implementation in this phase is restricted to ambient water sources (wells, ground water sources, rivers, lakes, etc) with a constant or profiled source water temperature. If you choose to use this component to model a ground loop above the water table (a “geo-thermal heat exchanger”) please be aware of the degree of compromise involved.

Figure 3 - 49 : Water-source heat exchanger tab on Heat transfer loop dialog.

Water-source heat exchanger checkbox

Tick this checkbox to specify a water-source heat exchanger as a heating and/or cooling source on the heat transfer loop. Ticking or un-ticking this checkbox will enable or disable the required water-source heat exchanger parameters below.

If the water-source heat exchanger is selected as the heating or cooling principal equipment for sizing, this checkbox is automatically ticked and is not allowed to be un-ticked.

Autosize water-source heat exchanger

Tick this checkbox to autosize the water-source heat exchanger during a system sizing run.

When this box is ticked:

If the water-source heat exchanger is selected as the heating or cooling principal equipment for sizing, then the peak Heat transfer loop heating or cooling capacity determined by autosizing will be used directly to update the heating or cooling capacity of the water-source heat exchanger. In other words, the water-source heat exchanger will get 100% of the autosized loop heating or cooling capacity, after consideration of the oversizing factor.

If the water-source heat exchanger is not selected as the heating or cooling principal equipment for sizing, then the peak Heat transfer loop heating or cooling capacity determined by autosizing will be multiplied by the Percent of autosized loop capacity (%) (see below) to determine and update the water-source heat exchanger heating or cooling capacity. In other words, the water-source heat exchanger will get a percentage of the autosized loop heating or cooling capacity as specified by its Percent of autosized loop capacity (%), after consideration of the oversizing factor. Note that in this case, the capacity fraction assigned to the water-source heat exchanger is not subtracted from the heat transfer loop heating or cooling capacity. In other words, the water-source heat exchanger size will not influence the size of the heat transfer loop.

Percent of autosized loop capacity (%)

This field is only enabled when the water-source heat exchanger is not selected as the current heating or cooling principal equipment for sizing and its ‘Autosize water-source heat exchanger’ checkbox (see above) is ticked.

When this field is enabled, during a system sizing run, the autosized loop heating or cooling capacity will be multiplied by the value in this field to get the water-source heat exchanger capacity. The resultant capacity will then be used to update the water-source heat exchanger capacity.

Once the heat transfer loop has been sized, edits made in this field will lead to automatic dynamic updating of the water-source heat exchanger capacity, based on the autosized loop heating or cooling capacity.