What is the Priority School Building Programme and design requirements?

The Priority School Building Programme (PSBP) is a centrally managed programme set up to address the needs of the schools most in need of urgent repair. Through the programme, 261 schools will be rebuilt or have their condition needs met by the Education Funding Agency (EFA). All schools within the programme will be delivered by the end of 2017. In May 2014, the Government announced a further phase of school development, known as PSBP2, which is a five-year programme operating between 2015 to 2021 and will undertake major rebuilding and refurbishment projects in schools and sixth form colleges in the very worst condition.

The Facility Output Specification forms the basis for the design of the PSBP Schools and has become the definitive guide to school design. The performance standards stipulated in PSBP requires three criteria, taken together, to be used to assess the risk of overheating of the building in the UK, using the geographically closest CIBSE Design Summer Year (DSY) weather file. A room or building that fails any two of the three criteria is classed as overheating:

· Criteria 1- Hours of Exceedance: During the occupied hours of the non-heating season (1st May to 30th September), the predicted operative temperature should not exceed the maximum adaptive temperature by 1°K or more, for less than 40 hours.

· Criteria 2- Daily Weighted Exceedance: For the severity of overheating, which can be as important as its frequency, the weighted exceedance of the temperature rise and its duration should be less than or equal to 6 during any occupied day of the non-heating season.

· Criteria 3- Upper Limit Temperature: The absolute maximum daily operative temperature for a room, beyond which the level of overheating is unacceptable, should not be greater than or equal to 4°K, than the maximum adaptive temperature (Top – Tmax), at any time.

With regards to internal air quality, TM52 criteria specifies that for natural ventilation or hybrid systems operating in natural mode:

· In all teaching and learning spaces when measured at seated head height, during the continuous period between the start and finish of teaching on any day, the average CO2 concentration of carbon dioxide should not exceed 1500 ppm.

· The maximum CO2 concentration should not exceed 2000 parts per million (ppm) for more than 20 minutes each day.

For mechanical ventilation or hybrid systems operating in mechanical mode, TM52 criteria specifies that:

· In all teaching and learning spaces when measured at seated head height, during the continuous period between the start and finish of teaching on any day, the average CO2 concentration of carbon dioxide should not exceed 1000 ppm.

· The maximum CO2 concentration should not exceed 1500 parts per million (ppm) for more than 20 minutes each day.

In addition to the mechanical and natural ventilation:

· At any occupied time, including teaching periods, the occupants should have the ability to lower the concentration of CO2 to 1000 ppm.

· The extreme maximum CO2 concentration of carbon dioxide should not exceed 5000 ppm during the teaching day.

Why Choose Hybrid Thermal Mixing?

Ideal Environment:

· The HTM is able to provide the ideal environment to school classrooms/ areas.

· The HTM system is designed to provide mixed tempered air during winter, boosted levels of ventilation during summer and secure night time cooling.

· The HTM system works in conjunction with natural ventilation provided by manual or automatic windows/ louvres.

· The HTM system can be used in single sided or cross flow ventilation strategies.

Exceptionally Low Power Consumption:

· The HTM system has an exceptionally low specific fan power.

· The HTM system comprises an intelligent and fully automatic control system coupled with a low energy ventilation system which switches between operational modes dependant on season, external/internal temperature conditions and indoor air quality (IAQ).

· The HTM control system is supplied as standard with full data logging facility, temperature and CO2 controls. With an optional BACnet module, each unit has the ability to output key performance data to a central BMS.

HTM Key Features

Two versions of Monodraught’s HTM system are available, the HTM F and the HTM FS. Each system (or pair of HTM FS systems) is able to produce 360 l/s of daytime ventilation and 530 l/s of night-time cooling. A powder coated steel frame makes the system robust and easy to install This frame supports a body constructed from specialist acoustic panels which when combined with a low energy fan means that the systems maximum daytime operation sound level is under 35dB. The low leakage external damper is integrated within the system and has a high U-Value of 1.2Wm2K and when combined with the internal damper allows the system to supply tempered fresh air throughout the year. A combination of an intelligent controls system and sensors measuring the room, external and mixed air temperatures & CO2 levels allows the system to automatically control the internal environment. This control system can also be utilised for the operation of additional VENTSAIR facade systems and has a full data logging facility.

HTM F – Key Features

· Low energy 380mm dia. fan - Low Speed

· 1 unit per classroom – Preferred option

· 500 mm Depth with 100mm gap required from

· ceiling

· Producing 340 l/s in Boost Mode

· Does not require any ducting

·

Non-vision high flow white linear angled grille

Full acoustic testing has been conducted at SRL (Sound Research Laboratories).

Sound reduction Index Measurements:

|

Ventilation Rate

|

63 Hz

|

125 Hz

|

250 Hz

|

500 Hz

|

1000 Hz

|

2000 Hz

|

4000 Hz

|

8000 Hz

|

|

300 l/s

|

53.4

|

52.6

|

50.4

|

43.5

|

36.7

|

31.0

|

24.7

|

24.7

|

Weighted Sound Reduction Index Rw (C:Ctr) = 31 dB

Tests were conducted with a standard 50 mm external louvre arrangement.

HTM FS - Key Features

· 2No. Units make up 1No. System

· 1No. System per classroom

· Above ceiling installation

·

300 mm depth (required void of 350mm)

· Each Unit Producing 180 l/s in Boost Mode

· High Performance Low Energy 280mm dia. fan – Low Speed

· Spiral wound ducting into classroom with 4-way diffuser

Sound power levels of the HTM FS per unit at 32% fan speed:

|

Ventilation Rate

|

63 Hz

|

125 Hz

|

250 Hz

|

500 Hz

|

1000 Hz

|

2000 Hz

|

4000 Hz

|

8000 Hz

|

|

150 l/s

|

46

|

50.8

|

44.4

|

39.7

|

35.4

|

25.7

|

17.9

|

22.9

|

Typical Installation - Operation Detail

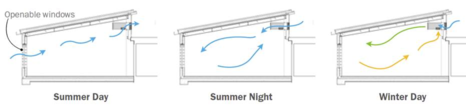

Cross Flow

Monodraught HTM system mounted at the rear of a room to assist with cross flow ventilation using openable windows on the facade. System automatically provides secure night time cooling through natural ventilation opening or fan assisted if required. Winter ventilation automatically modulates dampers to mix re-circulated air with external air to ensure optimum ventilation temperatures.

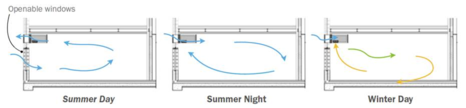

Single Sided Flow

Monodraught HTM system mounted on the facade (can be ducted to provide ventilation to the rear of deep plan rooms) to assist with single sided ventilation using openable windows. System automatically provides secure night time cooling through natural ventilation opening or fan assisted if required. Winter ventilation automatically modulates dampers to mix re-circulated air with external air to ensure optimum ventilation temperatures.

Additional Ventilation

Monodraught’s HTM is designed to work with and control a range of VENTSAIR Facade Ventilation System (VAF), as well as work in conjunction with other external openings such as windows.

The benefit of using VENTSAIR system is that they can be specified to suit different sized glazed frames or fitted with a flange to suit wall openings, as well provide controlled fresh air during the day and secure night time cooling. The HTM will automatically control the additional vents and the dampers can also be opened and closed manually via the systems control panel. These additional ventilation openings are often used in lieu of manual windows adding the benefit of secure night time cooling.

Control Strategy

The HTM incorporates a fully automatic control system based on a seasonal control strategy. The seasonal strategy is determined by time and date but is weather compensated to pick up unseasonal conditions. The system provides natural ventilation as the default method of ventilation indicating when manual windows or automatically opening dampers should be utilised to maximise IAQ and maintain comfort levels.

The control system incorporates a number of temperature sensors integral to the unit to monitor external temperature, mixed air temperature and supply air temperature. In addition, a wall mounted controller fitted with an internal temperature, CO2 sensor and user override are included as standard. Data is stored per minute on an integral data card for data analysis and compliance requirements.

Controls and user interface

Monodraught offer three wall controller options, each dependant on the room design and layout and the user’s requirements. One wall controller is required to be mounted within each room and will give the user certain functionality over the systems. Each controller houses temperature and CO2 sensors, with the exception of the Smart Screen Controller which requires a modular unit.

Openable Window: Allows the user to control the fan speed but will also indicate when they need to open windows to aid the system in providing ventilation.

Louvre Override: Allows the user to not only control the fan speed of the units but also regulate the amount that the VENTSAIR Facade system opens by if fitted.

HTM Case Study: Thomas Hickman School

·

System installed on 02/09/2014 and data logged until 02/03/2015

· Classroom is approximately 5 m x 9 m (area = 45 m2)

· Ceiling height 3.2 m (volume = 144 m3)

· East facing glazing approximately 7 m x 2 m which cannot be opened due to external noise

· Occupancy of 30 children and 2 adults

|

On a winter day:

|

|

On a spring day:

|

|

Data

|

Max

|

Min

|

Average

|

|

Data

|

Max

|

Min

|

Average

|

|

Room Temperature

|

23 ° C

|

21 ° C

|

22 ° C

|

|

Room Temperature

|

24 ° C

|

21 ° C

|

23 ° C

|

|

External Temperature

|

7 ° C

|

0 ° C

|

5 ° C

|

|

External Temperature

|

17 ° C

|

6 ° C

|

13 ° C

|

|

Mixed Air Temperature

|

25 ° C

|

15 ° C

|

19 ° C

|

|

Mixed Air Temperature

|

24 ° C

|

13 ° C

|

20 ° C

|

|

CO2

|

1780 ppm

|

435 ppm

|

1300 ppm

|

|

CO2

|

1580 ppm

|

505 ppm

|

1145 ppm

|

|

Results between 8:30 – 15:30

|

|

Results between 8:30 – 15:30

|

Further Information

300 mm depth (required void of 350mm)

300 mm depth (required void of 350mm)

System installed on 02/09/2014 and data logged until 02/03/2015

System installed on 02/09/2014 and data logged until 02/03/2015