Air-to-air heat pumps (Detailed model, both heating and cooling)

Introduction

The air-to-air heat pump (AAHP) model simulates the refrigerant side of an air-to-air heat pump in both heating and cooling conditions, with outside air as the heat source in heating mode and heat sink in cooling mode. The heating and cooling coils on the airside are modeled with the current ApacheHVAC simple heating/cooling coil models, using the total available heat pump capacity calculated by the air-to-air heat pump performance curves. Crankcase heating (in both heating and cooling modes) as well as defrost (in heating mode) are also included. This model uses default or user-defined air-to-air heat pump performance characteristics at rated conditions and seven performance curves to determine the air-to-air heat pump performance at off-rated conditions.

The seven air-to-air heat pump performance curves are (three for cooling, four for heating):

· AAHP cooling capacity temperature dependence curve

· AAHP cooling electric input ratio (EIR) temperature dependence curve

· AAHP cooling electric input ratio (EIR) part-load dependence curve

· AAHP heating capacity temperature dependence curve

· AAHP heating electric input ratio (EIR) temperature dependence curve

· AAHP heating electric input ratio (EIR) part-load dependence curve

· AAHP heating defrost electric input ratio (EIR) temperature dependence curve

The air-to-air heat pump model includes the heat pump compressor power consumption, crankcase heater power consumption, and defrost power consumption, but not the indoor (supply) fan power consumption. Supply fans for air-to-air heat pump systems must be modeled separately as an ApacheHVAC fan component.

The AAHP component is accessed through the toolbar button shown below. Clicking this button opens up the Air-to-air heat pumps – heat only, simple model (types) dialog.

Toolbar button for Air-to-air heat pumps (types) list

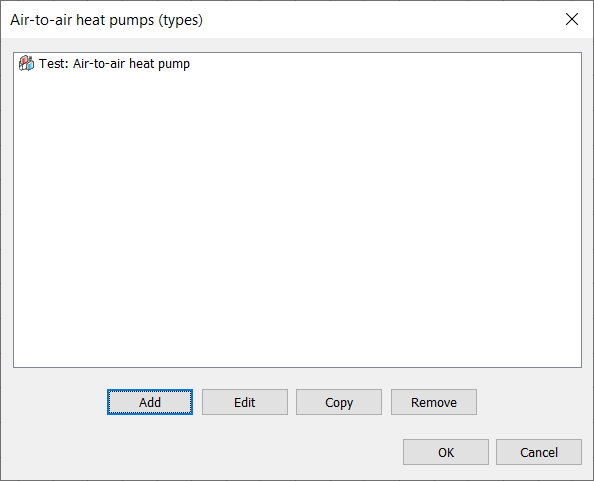

Toolbar button for Air-to-air heat pumps (types) listFigure 3-35: Air-to-air heat pumps – (types) dialog

Through this dialog, one or more AAHP types can be created and modified, and types may be copied or removed. Note that these types can be assigned to one or more individual coils (such as multiplexed single-zone systems), with each layer having a separate instance of that particular AAHP type.

Heat pump equipment

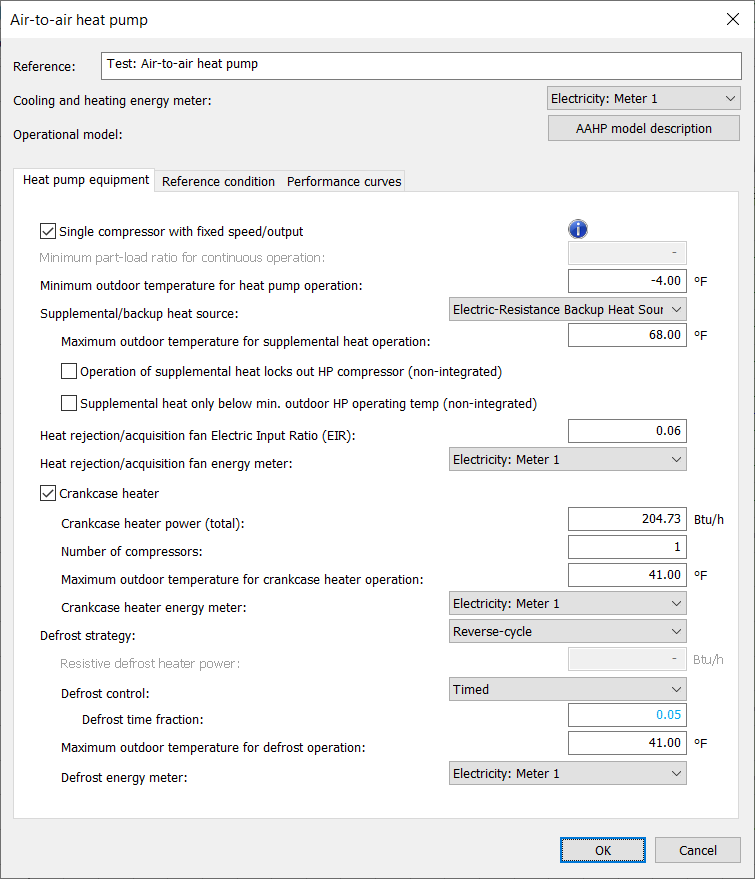

The first tab seen when editing an AAHP type is the “Heat pump equipment” tab, shown in Figure 44 below.

Figure 44: Air-to-air heat pump dialog, Heat pump equipment tab

Following is an explanation of each item in the Heat pump equipment tab.

Reference: A description of the particular AAHP, which is used in the coil selection dialog boxes and elsewhere.

Cooling and heating energy meter: The default energy meter through which all AAHP energy is tracked.

Operational model: Clicking the “AAHP model description” button brings up a dialog reference showing the various terms and abbreviations used in defining the model, which are shown throughout the tabs.

Single compressor with fixed speed/output: Selecting this item denotes that the heat pump compressor is only capable of single-speed operation. At low load conditions, the heat pump will cycle on/off as required to meet load. Note that the selection of performance curves must include the effect of this cycling at low part-load ratios.

Minimum part-load ratio for continuous operation: For a variable- or multi-speed compressor, this is the lowest part-load ratio (or stage) at which the heat pump will operate without cycling. At lower part-load ratios, the unit will cycle on/off to meet load. This option is disabled when the single compressor option is checked.

Minimum outdoor temperature for heat pump operation: At temperatures below this minimum, the heat pump does not operate. Functionally, this is the temperature below which the heating COP drops below 1.0, meaning that electric resistance becomes more efficient. (Units: °F or °C)

Supplemental/backup heat source: This dropdown allows selection of the supplemental or backup heat source, used when temperature limits are exceeded or when the HP capacity is not sufficient to meet the full heating load. This heat source is a “Generic heat source” type as defined in Section 3.2.

Maximum outdoor temperature for supplemental heat operation: At temperatures above this value, supplemental heating is unavailable. This temperature should be set sufficiently high, especially in the case of a non-integrated compressor, to ensure sufficient capacity all throughout the range of expected outdoor temperatures. (Units: °F or °C)

Operation of supplemental heat locks out HP compressor (non-integrated): This option denotes a non-integrated compressor. For a non-integrated compressor, only one of the HP or supplemental heat source will operate.

Supplemental heat only below min. outdoor HP operating temp (non-integrated): When the compressor is non-integrated, selecting this option will prevent supplemental/backup heat from switching on unless the outdoor temperature is below the minimum limit. Note that this may result in insufficient capacity at temperatures just above that minimum as the heat pump may not be able to meet the full load depending on performance curves.

Heat rejection/acquisition fan Electric Input Ratio (EIR): The ratio of input power for the heat rejection/acquisition fan to the capacity of the unit.

Heat rejection/acquisition fan energy meter: An energy meter to track heat rejection/acquisition fan energy. This may be different from the main energy meter for the AAHP itself.

Crankcase heater: Ticking this box enables crankcase heating, which is used to ensure the refrigerant is not the coldest component of the system in order to prevent mixing of oil into the refrigerant stream, which can lead to equipment failure.

Crankcase heater power (total): The power consumption of the electric resistance crankcase heater. (Units: Btu/h or W)

Number of compressors: Compressor count; each compressor will usually have its own heater.

Maximum outdoor temperature for crankcase heater operation: Above this temperature, the crankcase heater will not operate. It is assumed, then, that the compressor temperature would be high enough at this point to prevent equipment damage.

Crankcase heater energy meter: An energy meter to track crankcase heating energy. This may be different from the main energy meter for the AAHP itself.

Defrost strategy: This dropdown enables selection of the means by which the unit will defrost while in heating mode. Options are reverse-cycle, meaning that the unit will temporarily enter cooling mode to defrost the coils; or resistive, in which a resistance heating element will provide the heat to defrost the coils.

Resistive defrost heater power: The power requirement of the resistive heating element, if the corresponding defrost strategy is selected. (Units: Btu/h or W)

Defrost control: This dropdown selects whether defrost is activated based on compressor runtime (Timed), or when the program detects potential for frost accumulation (On-demand).

Defrost time fraction: For Timed defrost, this is the fraction of compressor runtime that defrost is activated. The default of 0.05 denotes 3 minutes in defrost out of every 60 minutes of compressor runtime. This option is disabled for On-demand defrost.

Maximum outdoor temperature for defrost operation: Below this temperature, it is assumed that the potential for frost accumulation, and thus the need for defrost, is negligible. As such, this value should be high enough above freezing (typical values of 41°F or 5°C) to reflect that assumption.

Defrost energy meter: An energy meter to track defrost energy. This may be different from the main energy meter for the AAHP itself.

Reference condition

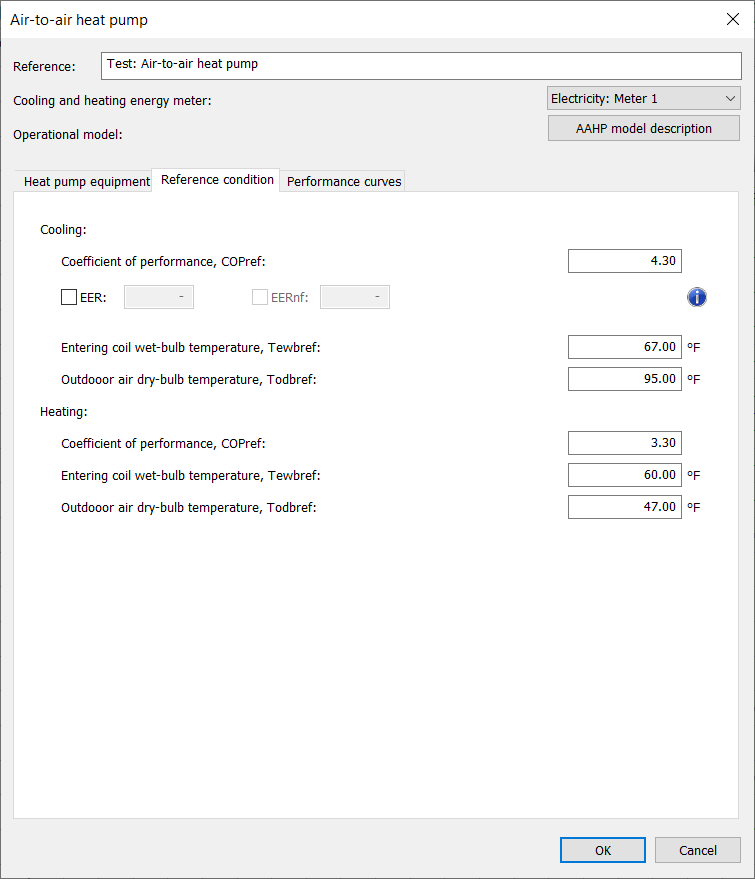

The second tab seen when editing an AAHP type is the “Reference condition” tab, shown in Figure 45 below.

Figure 45: Air-to-air heat pump dialog, Reference condition tab

Following is an explanation of each item in the Heat pump equipment tab.

Cooling

Coefficient of Performance, COPref: The ratio of cooling provided (in Btu/h or W) to input power (in the same unit) at reference conditions. This value is interlocked with EER and EERnf, and is only editable when neither of those two boxes are checked.

EER: The Energy Efficiency Ratio of cooling provided (in Btu/h) to input power (in W). This value is only editable when the box is checked, and the EERnf box is unchecked.

EERnf: As above, the EER except with fan energy excluded. For certain modeling protocols, fan energy is required to be accounted separately from compressor energy when modeling packaged equipment. This value is only editable when both the EER and EERnf boxes are checked.

Entering coil wet-bulb temperature, Tewbref: Wet-bulb temperature at the coil entry at reference conditions. This and the following item are used to normalize the AAHP performance curves such that the rated COP is returned at rated design reference conditions. (Units: °F or °C)

Outdoor air dry-bulb temperature, Todbref: Outdoor air temperature at rated design conditions. (Units: °F or °C)

Heating

Coefficient of Performance, COPref: The ratio of heating provided (in Btu/h or W) to input power (in the same unit) at reference conditions.

Entering coil wet-bulb temperature, Tewbref: Wet-bulb temperature at the coil entry at reference conditions. This and the following item are used to normalize the AAHP performance curves such that the rated COP is returned at rated design reference conditions. (Units: °F or °C)

Outdoor air dry-bulb temperature, Todbref: Outdoor air temperature at rated design conditions. (Units: °F or °C)

Performance curves

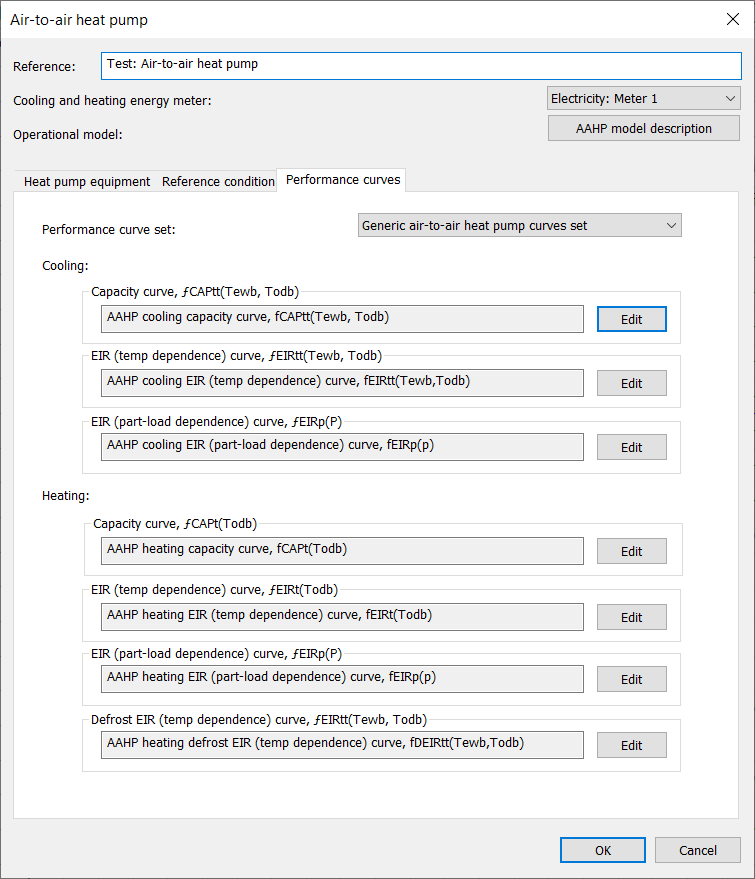

The final tab seen when editing an AAHP type is the “Performance curves” tab, shown in Figure 46 below.

Figure 46: Air-to-air heat pump dialog, Performance curves tab

Following is an explanation of each item in the Heat pump equipment tab.

Performance curve set: This dropdown enables selection of various sets of AAHP performance curves from the Apache library.

Cooling

There are three editable curves that define cooling performance together with rated performance and unit capacity:

· AAHP cooling capacity temperature dependence curve

· AAHP cooling electric input ratio (EIR) temperature dependence curve

· AAHP cooling electric input ratio (EIR) part-load dependence curve

Heating

There are three editable curves that define cooling performance together with rated performance and unit capacity:

· AAHP heating capacity temperature dependence curve

· AAHP heating electric input ratio (EIR) temperature dependence curve

· AAHP heating electric input ratio (EIR) part-load dependence curve

· AAHP heating defrost electric input ratio (EIR) temperature dependence curve

Each curve is editable by clicking the corresponding Edit button.